You can directly prevent catastrophic blowouts and boost fleet safety. Proactive heavy truck tire repair is your best strategy against the 8,000 large truck crashes caused by tire failure annually. This essential practice also cuts your operational costs. It enhances fleet reliability, minimizes downtime, and keeps your fleet generating revenue. A proactive tire maintenance program delivers clear results.

The Critical Link Between Tire Repair and Fleet Safety

Your fleet’s safety record depends directly on the condition of your tires. A proactive approach to tire maintenance is not just about compliance; it is a fundamental strategy to protect your drivers, your assets, and the public. You can build a stronger, safer fleet by focusing on the critical link between tire repair and overall fleet safety.

Preventing Catastrophic Tire Blowouts

You can prevent most catastrophic blowouts with diligent maintenance. These dangerous events often result from predictable and preventable issues. Understanding the causes empowers you to take control.

Common causes of tire failure include:

- Underinflation: This is a primary culprit. An underinflated tire flexes excessively, building up intense heat that weakens its internal structure.

- Overloading: Exceeding a tire’s load rating puts immense stress on its components, leading to rapid wear and potential failure.

- Worn Treads: Insufficient tread depth makes a tire more vulnerable to punctures from road hazards and reduces its structural integrity.

- Road Damage: Impacts from potholes or debris can cause immediate or hidden damage that compromises the tire.

The consequences of a blowout are severe. When a tire on a heavy truck explodes, the driver can instantly lose control. The sheer force can cause the truck to swerve into other lanes or even roll over.

A Public Safety Crisis A tire blowout on commercial trucks creates a chaotic and deadly scene. Flying debris can strike other vehicles, and a loss of control can trigger multi-car pileups. This turns a preventable vehicle failure into a major public safety incident, putting everyone on the road at risk. Your commitment to tire maintenance directly protects the community.

Regular inspections and timely repairs are your best defense against these devastating blowouts.

Correcting Hidden Damage Before It Fails

The most dangerous threats to your tires are often the ones you cannot see. A visual check might miss critical internal damage that can lead to sudden failure under load. Professional inspections are essential to uncover these potential hazards.

Technicians can identify issues invisible to the naked eye, such as:

- Internal cracks and separations

- Belt defects from manufacturing

- Mounting damage

- Heat damage along the sidewall and belts

An impact from a pothole can weaken the tire’s internal structure without leaving a visible mark. This hidden damage creates a ticking time bomb. The tire may seem fine, but the added stress of a heavy load or high speed can cause it to fail without warning. A comprehensive heavy truck tire repair program ensures these issues are found and fixed, safeguarding the safety of the driver and your entire fleet.

Ensuring Optimal Traction and Braking

Your truck’s ability to stop safely rests on the small patch of rubber connecting it to the road. Proper tire condition is non-negotiable for reliable braking and traction. Both over-inflation and under-inflation severely compromise safety.

- Underinflated Tires: An underinflated tire has a less effective contact patch with the road. This reduces traction and can significantly increase braking distances, especially during emergency stops.

- Overinflated Tires: An overinflated tire has a smaller, rounded contact patch. This also reduces grip and can make the vehicle unstable during hard braking.

Tread depth is equally critical, particularly in poor weather. Deep treads are designed to channel water away, preventing hydroplaning and maintaining grip on wet roads. As the tread wears down, this ability diminishes, increasing stopping distances and the risk of losing control. For a fleet operating in diverse conditions, maintaining proper tire inflation and tread depth is a cornerstone of operational safety.

Financial Wins from Proactive Heavy Truck Tire Repair

A proactive approach to tire maintenance does more than keep your fleet safe; it directly boosts your bottom line. You can unlock significant financial advantages by shifting from a reactive mindset to a strategic one. This strategy turns a necessary expense into a powerful tool for improving profitability and operational efficiency.

Reduce Costs with Repair Over Replacement

You can save a substantial amount of money by choosing professional repairs over premature tire replacement. A high-quality tire is a significant investment, and discarding one with remaining service life is like throwing money away. However, not every damaged tire is a candidate for repair. Following industry-recognized standards ensures that your repairs are both safe and durable.

The Tread Rubber and Tire Repair Materials Manufacturers Group (TRMG) provides clear guidelines for technicians. For a tire to be safely repaired, several conditions must be met:

- Repairs are prohibited on the sidewall or shoulder area.

- The process must seal both the inner liner and the puncture itself.

- Only qualified technicians should perform the work using approved methods.

- Temporary solutions like boots or simple blowout patches are not considered safe or permanent repairs.

Adhering to these standards means a repaired tire can be returned to service with confidence, extending its life and maximizing your initial investment.

Maximize Fuel Efficiency and Lower Expenses

Fuel is one of the largest operating expenses for any fleet. You can directly lower this cost by focusing on your tires. The connection between tire condition and fuel consumption is undeniable.

Fuel Savings in Numbers 📈 Maintaining proper tire inflation can improve your truck’s fuel efficiency by up to 3%. For a large fleet, this small percentage translates into thousands of dollars in annual savings. Conversely, a tire that is just 20% underinflated can reduce your fuel economy by 2-3%.

Rolling resistance is another major factor. This is the energy your truck must use to overcome the friction between the tire and the road. It accounts for roughly one-third of a heavy truck’s total fuel consumption. A well-maintained and properly inflated tire minimizes this resistance. A mere 3% reduction in rolling resistance can lead to a 1% savings in fuel, directly impacting your operational budget.

Minimize Downtime and Protect Revenue

Your commercial trucks only generate revenue when they are on the road. Unexpected breakdowns are a direct threat to your profitability, leading to service call fees, delivery delays, and damage to your reputation. A consistent heavy truck tire repair program is your best defense against these costly downtimes.

Scheduled maintenance allows you to find and fix potential problems before they cause catastrophic failures. Tire blowouts, often resulting from under-inflation or wear, are a leading cause of roadside breakdowns. By addressing these issues during planned service windows, you prevent them from escalating into emergencies. Modern predictive technologies even use sensors to forecast tire issues, allowing you to schedule service proactively. This approach helps you:

- Reduce unscheduled maintenance events.

- Extend tire life and lower replacement costs.

- Improve vehicle utilization and on-time delivery rates.

By preventing unexpected breakdowns, you keep your fleet moving, protect your revenue streams, and maintain customer trust.

Implementing an Effective Fleet Tire Management Program

An effective fleet tire management program is your roadmap to enhanced safety and profitability. You build a system that prevents failures, cuts costs, and keeps your fleet on the move. This proactive approach moves you from reacting to emergencies to controlling your operations. It involves clear inspection rules, scheduled professional service, and precise vehicle alignment.

Establish Rigorous Inspection Protocols

You can catch most tire problems early with strict daily checks. Empower your drivers to be the first line of defense in your tire maintenance strategy. A thorough pre-trip inspection is essential for identifying issues before a truck hits the road, ensuring safety and reducing costly roadside repairs.

Your drivers’ daily inspection checklist should include:

- Tire Pressure: Use a gauge to confirm proper inflation. A tire under 50% of its maximum PSI is an out-of-service violation.

- Tread Depth: Steer tires need at least 4/32 inches, while drive and trailer tires need 2/32 inches.

- Sidewalls: Look for cuts, bulges, or exposed cords on both inner and outer sidewalls.

- Rims and Lug Nuts: Check for damage, and look for rust streaks around lug nuts, which signal they are loose.

For more advanced oversight, fleet managers can integrate technology. Tire Pressure Monitoring Systems (TPMS) provide real-time data on pressure and temperature, sending instant alerts to the driver and fleet managers. This technology allows you to track tire history, identify recurring problems, and schedule regular truck maintenance more effectively. By combining hands-on inspecting tires with smart technology, you create a powerful safety net for your entire fleet.

Schedule Professional Repairs and Balancing

You must schedule professional service to maximize tire life and ensure safety. While daily checks are crucial, only trained technicians can perform the detailed repairs and balancing your commercial trucks require. Set a schedule for professional tire inspections every 6,000 to 8,000 miles. This routine truck maintenance catches issues that drivers might miss.

Wheel balancing is a critical but often overlooked part of effective tire maintenance. An unbalanced tire wears out much faster.

An imbalanced tire can lose 20-25% of its potential life due to uneven wear. Fleets that implement balancing have seen tire mileage increase by up to 30%, extending tire life from 55,000 miles to over 85,000 miles.

You should schedule balancing whenever you install a new tire or if a driver reports vibrations. Timely repairs and balancing are not just about maintenance; they are a direct investment in your fleet’s longevity and performance. Fleet managers who prioritize this regular truck maintenance see significant returns.

Integrate Tire Rotation and Alignment

You can further extend tire life and improve vehicle handling by adding tire rotation and alignment to your regular truck maintenance plan. Proper alignment ensures your truck’s wheels are correctly angled relative to the road and each other. Misalignment causes rapid, uneven tire wear and can make the truck harder to control.

| Alignment Issue | Impact on Tire Wear |

|---|---|

| Improper Camber | Excessive wear on the inside or outside edge. |

| Incorrect Toe | Rapid, scrubbing wear across the tread. |

Misalignment forces the engine to work harder, reducing fuel efficiency and increasing driver fatigue. Integrating regular tire changes and alignment checks into your comprehensive fleet management strategy is essential. This practice ensures your tires wear evenly, your truck handles safely, and you get the maximum value from every tire. These comprehensive maintenance services are a cornerstone of a well-run fleet, protecting your assets and your drivers. This level of tire maintenance is what separates a good fleet from a great one.

The Role of Quality Materials in Fleet Reliability

You can ensure the long-term success of your repairs by using high-quality materials. The tools and patches you choose directly impact your fleet’s safety and operational uptime. Investing in professional-grade supplies is not an expense; it is a crucial step toward building a more dependable and profitable operation.

Why Professional-Grade Repair Tools Matter

You must equip your technicians with the right tools for safe and effective repairs. Using substandard equipment creates enormous risks, including catastrophic tire blowouts and tragic workshop accidents. Professional-grade tools, from heavy-duty jacks to calibrated air gauges and carbide buffing wheels, ensure every repair is performed correctly. Cutting corners with improper tools can lead to tire failures on the road, endangering your driver and the public. It also puts your technicians in danger, as damaged rims and improper procedures have led to fatal incidents during routine maintenance.

The Impact of High-Quality Tire Patches

The quality of your tire patch determines the durability of the repair. A cheap patch can fail under pressure, leading to slow leaks or a sudden blowout. High-quality patches, like dual-cure patches, create a stronger, more reliable bond.

| Feature | Traditional Patches | High-Quality Dual-Cure Patches |

|---|---|---|

| Bond Strength | Weaker, prone to failure | Robust, prevents air leaks |

| Durability | Inconsistent | Designed for long-lasting repairs |

| Risk of Failure | Higher due to manual process | Minimized with standardized curing |

Using a superior patch ensures the repair maintains the tire’s structural integrity. This choice enhances safety and extends the service life of your assets, giving you confidence in every truck you put on the road.

Partnering with SUNSOUL for Dependable Supply

You need a supplier that delivers more than just products. A strong partnership ensures you have a stable supply of dependable materials. SUNSOUL is a leading manufacturer that provides end-to-end solutions, from R&D to after-sales support. With a production capacity of over two million patches monthly, SUNSOUL guarantees a stable global supply for your fleet.

“I run a fleet of delivery trucks in Brazil. SUNSOUL patches keep my vehicles on the road. I save money and avoid breakdowns.” — João, Fleet Manager

Partnering with SUNSOUL gives you access to competitive pricing, technical training, and global service hubs that resolve issues within 72 hours. This level of support boosts your operational reliability and protects your bottom line.

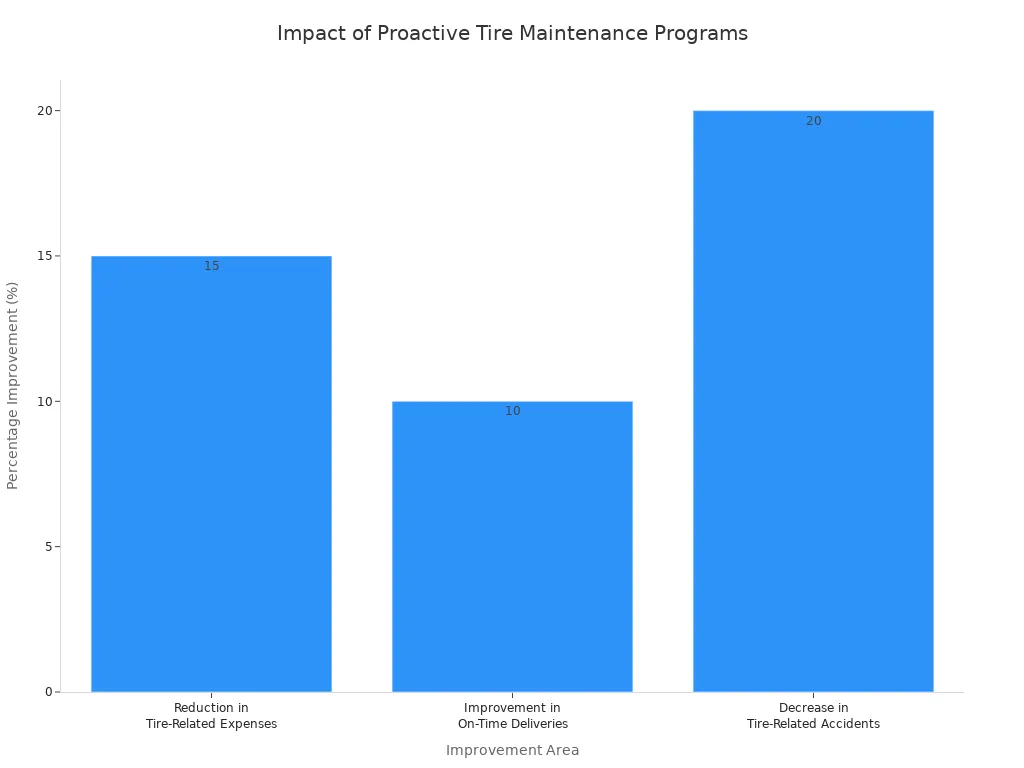

You can build a safer, more profitable fleet. A consistent heavy truck tire repair program is a pillar of modern fleet tire management. This proactive strategy boosts reliability and delivers proven results for your truck fleet.

| Metric | Standard Program | Optimized Program | Savings |

|---|---|---|---|

| Cost Per Mile | $0.028 | $0.019 | -32% |

| Roadside Failures/Year | 8.4 per 50 trucks | 1.2 per 50 trucks | -86% |

| Unplanned Downtime | 168 hours | 24 hours | -86% |

Take immediate action to protect your assets and personnel.

- Implement a digital system to track tire status and history.

- Set clear tire maintenance standards for pressure and tread depth.

FAQ

What is the most common cause of tire blowouts?

Underinflation is the number one cause of blowouts. It makes the tire flex too much. This builds intense heat that weakens the tire’s internal structure, leading to catastrophic failure. You can prevent this with daily pressure checks.

How often should I schedule professional tire inspections?

You should schedule professional inspections for your trucks every 6,000 to 8,000 miles. Technicians can spot hidden damage and perform critical balancing. This routine service extends tire life and prevents unexpected failures on the road.

Can I repair a tire with sidewall damage?

No, you must never repair a tire with sidewall damage. Industry standards from groups like the TRMG prohibit it. Safe repairs are only allowed in the tread area. A damaged sidewall compromises the tire’s entire structure and requires immediate replacement.

How much can proper tire maintenance save on fuel?

You can improve your fleet’s fuel efficiency by up to 3% with proper tire inflation. For a large fleet, this translates into thousands of dollars in annual savings. A well-maintained tire reduces rolling resistance and directly lowers your operational expenses.

Why should I choose a supplier like SUNSOUL?

You need a partner who guarantees reliability. SUNSOUL produces over two million patches monthly, ensuring a stable supply. Their high-quality patches, technical support, and fast service help you perform durable repairs, minimize downtime, and keep your fleet running safely.