A flat tire requires a safe, permanent repair. This action is essential for maximizing your tire’s lifespan. A successful tire repair depends on one thing. You must match the truck tire patch to the specific tire damage. This prevents further tire damage.

Pro Tip: Always use high-quality materials for your tire. Trusted tire repair kits ensure a durable repair. The best tire repair kits contain a strong tire patch. For a lasting fix on your tire, your tire repair kits must be reliable. SUNSOUL, a global leader, provides such quality in their tire repair kits.

Why the Right Truck Tire Patch is Non-Negotiable

Choosing the correct truck tire patch is not just about fixing a flat tire; it is a critical decision for your safety and your vehicle’s health. A cheap or incorrect patch creates a weak point on your tire. This weak point can fail under the immense pressure and heat of highway driving. You must treat every tire repair with professional attention.

Ensuring an Airtight Seal for Safety

Your safety on the road depends on a perfect, airtight seal. A proper repair prevents air from escaping the tire. This maintains correct inflation and vehicle stability. A slow leak from a bad repair might not be enough to trigger your Tire Pressure Monitoring System (TPMS). Worse, sealant from a poor repair can even clog the sensor’s port. This means your system may fail to warn you about a dangerous drop in tire pressure, giving you a false sense of security. A reliable repair ensures your safety systems can do their job.

Preventing Blowouts and Secondary Damage

A failed repair is a ticking time bomb. When a patch fails, it can allow moisture and dirt to penetrate the tire’s inner structure. This contamination weakens the steel belts and fabric plies, leading to tread separation or a sudden, catastrophic blowout. Following industry-recommended practices, like those from the Tread Rubber and Tire Repair Materials Manufacturers Group (TRMG), is essential for a permanent repair.

Pro Tip: A Methodical Repair is a Safe Repair A trained technician follows key steps to ensure the tire remains structurally sound. This includes assessing the damage location, thoroughly cleaning the area, applying the patch to the inner liner, and ensuring a strong bond. This process prevents secondary damage and keeps your tire in service longer.

The Economic Impact of a Lasting Repair

A quality repair saves you money in the long run. A failed repair means more than just another flat tire. It costs you in several ways:

- Expensive roadside service calls

- Lost time and delivery delays

- The high cost of a replacement tire

- Potential damage to your wheel or vehicle during a blowout

Investing in a proper repair with high-quality materials from the start is the most cost-effective choice. It extends the life of your tire, maximizes your investment, and keeps your truck operating efficiently.

Decoding Patch Types for Your Tire Repair

You cannot grab just any patch for a tire repair. Different types of tire damage on different types of tires require specific solutions. Understanding the main patch categories helps you make the right choice. This knowledge ensures your repair is safe and permanent. Your choice directly impacts the longevity of your tire.

Patch-Only vs. Combination Units

You have two primary options for sealing a puncture. You can use a patch-only unit or a combination unit. A simple patch seals the tire’s inner liner. This stops air from leaking. However, it does not fill the puncture hole itself. This leaves a path for moisture and dirt to enter the tire structure, which can cause tire damage over time.

A combination unit, or patch-plug, offers a more complete repair. This single unit both seals the inner liner and fills the puncture path. Auto service professionals often use these for a comprehensive, permanent repair. Many high-quality tire repair kits include these units. Using a combination unit from your tire repair kits provides several key advantages:

- It offers a quick fix with long-lasting durability.

- It provides a dependable solution that helps the tire keep its structural integrity.

- It saves you time and money by avoiding a costly tire replacement.

- It ensures optimal performance by maintaining the tire’s original balance and stability.

Note: For a simple puncture, a combination unit from your tire repair kits is the industry-preferred method. It provides the most secure and durable seal for your tire. Always check your tire repair kits for these superior components. The best tire repair kits will contain them.

Bias-Ply vs. Radial Patches

Tires are built in two different ways: bias-ply or radial. You must match the patch to the tire’s construction. A bias-ply tire has crisscrossing cords. A radial tire has cords running straight across, from bead to bead. This difference affects how the tire flexes.

Using the wrong patch type creates a dangerous situation. If you place a stiff bias-ply patch on a flexible radial tire, you create a hard spot. The tire will no longer flex correctly. This stress can cause the repair to fail and lead to severe tire damage. In bias-ply tires, the sidewall strength is omnidirectional, which allows for some sidewall patching. However, radial tires have unidirectional strength. A small break in a radial sidewall significantly weakens the tire, making a repair very unlikely to hold. A mismatched repair can lead to tire failure. Always use a radial patch for a radial tire and a bias-ply patch for a bias-ply tire. Your tire repair kits should specify the patch type. Make sure your tire repair kits match your vehicle’s needs.

Chemical vs. Heat Vulcanization

Vulcanization is the process that bonds the patch to the tire. It creates a strong, seamless repair. This happens in two ways: chemical vulcanization or heat vulcanization.

Chemical vulcanization, also known as cold vulcanization, uses a special adhesive. This adhesive creates a chemical reaction that bonds the tire patch to the tire. This is the most common method for puncture repairs. You will find this system in most over-the-counter tire repair kits. Leading manufacturers like SUNSOUL produce advanced chemical cure patches for their tire repair kits, ensuring a reliable bond without complex equipment.

Heat vulcanization, or hot vulcanization, uses intense heat and pressure. This process forges an incredibly strong bond between the rubber materials. It is the preferred method for larger, more serious repairs.

| Repair Type | Description | Best Use Case |

|---|---|---|

| Section Repair | Fills large injuries where cords are cut. New rubber and ply layers are added. | Severe tire damage |

| Spot Repair | Fixes minor external cracks or gouges. A raw rubber patch is applied. | External tire damage |

| Stripping | Adds a new layer of rubber to the inner liner when cords are exposed. | Thinning inner liner |

Heat vulcanization offers superior results for heavy-duty applications. The finished repair has unique qualities:

- Durability: The vulcanized rubber is extremely tough and resists high wear.

- Elasticity: The tire maintains its ability to stretch and compress without losing shape.

- Temperature Resistance: The repair can handle extreme heat and cold.

While you might use tire repair kits with chemical cement for a standard puncture, a professional shop will use heat vulcanization for a major truck tire patch repair.

Sizing and Selecting the Correct Tire Patch

Choosing the right size for your truck tire patch is a science, not a guess. A patch that is too small will fail to seal the injury, while one that is too large can create a stiff, unbalanced spot on your tire. You must precisely match the patch to the specific tire damage to ensure a safe and lasting repair. This precision begins with a thorough inspection and accurate measurement.

Measuring the Puncture Injury

Before you even think about a repair, you must fully understand the tire damage. A complete inspection gives you the full picture of your tire’s health. You should follow a systematic process for every tire.

- Visual Inspection: You need to carefully examine the entire tire. Look for punctures, cuts, or bulges on the tread, sidewalls, and between the tread grooves.

- Check Tread Depth: Use a gauge to measure the tread. If your tire has less than 2/32 inches of tread, you must replace it. A repair is not a safe option.

- Check for Uneven Wear: Feel the surface of the tire. Bald spots or strange wear patterns can point to bigger problems with alignment or inflation that a simple repair will not fix.

- Inspect Valve Stems: Look for any cracks or leaks on the valve stem. A faulty stem can mimic the symptoms of a puncture.

After your initial inspection, you must accurately measure the puncture itself. Guessing the size of the injury is a common mistake that leads to a failed repair. Professionals use special tools to eliminate guesswork. Many high-quality tire repair kits include these instruments.

Pro Tip: Use a Color-Coded Tool for Accuracy An injury measuring tool makes your tire repair work easier and faster. You simply insert the tool into the puncture, and the point where it stops tells you the exact size of the tire damage. These tools often use color codes to help you select the right patch from your tire repair kits.

- Green: 3mm injury

- Yellow: 6mm injury

- Red: 8mm injury

- Blue: 10mm injury

- Orange: 13mm injury

Using a dedicated tool from your tire repair kits ensures you have the correct data to select the perfect tire patch.

Matching Patch Size to Damage

Once you know the exact size of the puncture, you can select the correct patch. The rule is simple: the patch must be significantly larger than the prepared injury area. A proper repair requires you to buff the area around the puncture to create a clean surface for adhesion. The patch must cover this entire buffed area.

As a general guideline, the patch should extend at least 1/2 inch (about 13mm) beyond the edges of the tire damage in all directions. This overlap ensures the patch has enough surface area to create a strong, airtight seal on the tire’s inner liner. Your tire repair kits should include a chart or instructions that match injury sizes to the recommended patch sizes. Always follow the manufacturer’s recommendations included with your tire repair kits. Choosing the right size prevents stress on the edges of the repair and maintains the flexibility of the tire.

The Importance of Quality Adhesion

A patch is useless without a powerful bond. The adhesive, or vulcanizing fluid, is the critical link that fuses the tire patch to the tire. Quality adhesion creates a permanent, leak-proof seal that becomes part of the tire itself. The best tire repair kits use advanced chemical adhesives to achieve this.

These adhesives, often called fast-dry rubber cement, create a chemical reaction that vulcanizes the patch at room temperature. This process ensures a durable, long-term repair. Some tire repair kits offer different types of patches and adhesives.

- Chemical Cure Patches: These use a chemical adhesive to form an incredibly strong bond. They are the standard for permanent repairs and are known for high strength and durability.

- Cold Patches: These use a simpler adhesive for quick, emergency repairs. While easy to apply, they are generally considered a temporary solution and are less durable than a chemical cure repair.

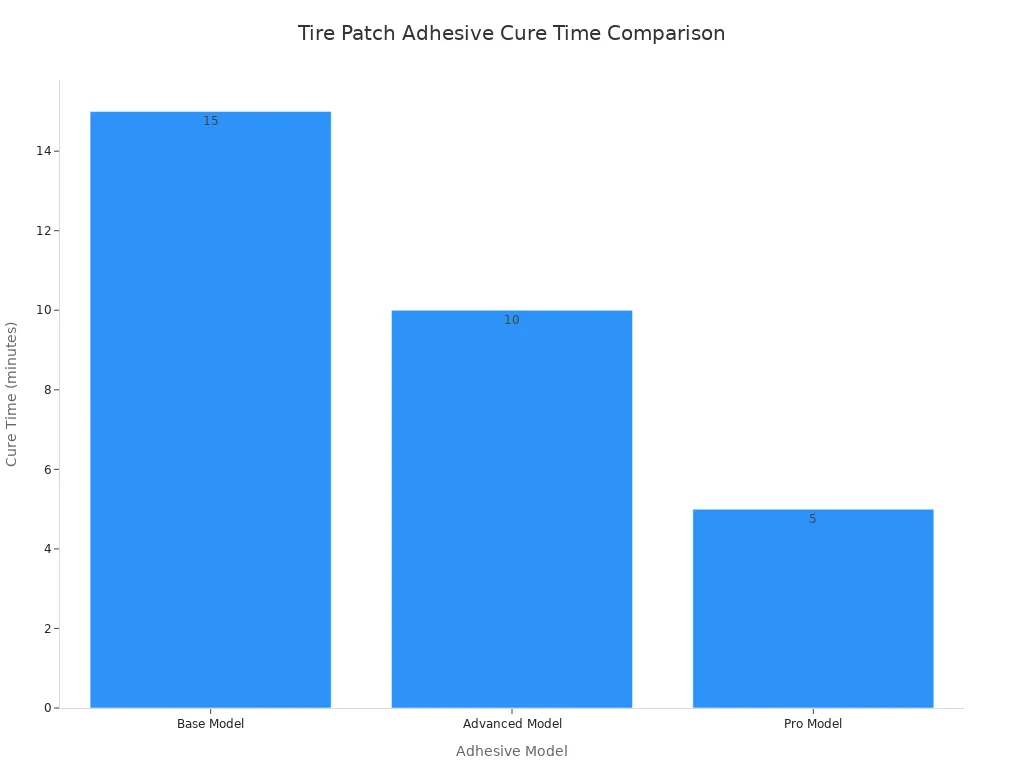

The time it takes for the adhesive to cure depends on the product and the temperature. Lower temperatures often require a longer curing time. However, advanced formulas in modern tire repair kits have significantly reduced this waiting period.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cure Time | 15 minutes | 10 minutes | 5 minutes |

| Temp. Range | -20°C to 80°C | -30°C to 90°C | -40°C to 100°C |

As you can see, some professional-grade tire repair kits include accelerators that cure in as little as five minutes, drastically reducing vehicle downtime.

Investing in high-quality tire repair kits with superior adhesives is essential. It guarantees the integrity of your repair and the safety of your tire for the rest of its service life.

Common Mistakes in Tire Patch Application

You can have the best tire repair kits available, but a simple mistake can lead to a failed repair. Avoiding common errors is just as important as choosing the right tools. A proper repair ensures your tire remains safe for its full service life. Understanding these pitfalls helps you get the job done right the first time and avoid a future flat tire.

Using the Wrong Patch Type for the Tire

You must always match the patch to the tire construction. Using a bias-ply patch on a radial tire is a critical error. However, the biggest mistake is attempting a repair on a tire with non-repairable tire damage. The Tire Industry Association (TIA) has clear guidelines. Your tire cannot be safely repaired if it has certain types of tire damage. Even the most advanced tire repair kits cannot fix these issues.

Warning: Unrepairable Tire Damage ⚠️ You must replace your tire if you find any of the following issues. A repair is not a safe option.

- Punctures larger than 3/8” for your truck’s steel-belted tire.

- Any damage on the tire sidewall, including cuts or bulges.

- Damage from running the tire with low air pressure.

- Cracks from dry rot, which make the tire brittle.

- Damage that exposes the tire’s internal cords.

Selecting an Incorrectly Sized Patch

Size matters when you select a tire patch. A patch that is too small will not completely cover the prepared area around the puncture. This allows air to leak, defeating the purpose of the repair. On the other hand, a patch that is too large can create a stiff, inflexible spot on your tire. This affects the tire’s balance and can cause the repair to fail over time. Your tire repair kits should include a guide for matching the patch size to the tire damage. Always follow these instructions for a successful outcome.

Skipping Essential Surface Preparation

A strong bond depends on a perfectly clean surface. Many people skip this crucial step. You must use a pre-buff cleaner from your tire repair kits before you do anything else. These special cleaners dissolve and remove contaminants from the tire’s inner liner. Things like dirt and mold-release lubricants will prevent the truck tire patch from sticking correctly. If you skip this step, your buffing wheel can get clogged, and the residue will ruin the adhesion. A clean surface is essential for a permanent fix for your flat tire. Your tire repair kits contain everything you need for a reason.

Mixing Incompatible Repair Brands

You might think a patch is a patch and cement is cement. This is a dangerous assumption. Manufacturers design their repair products to work together as a complete system. Mixing a patch from one brand with a chemical cleaner or cement from another can cause your tire repair to fail. The chemicals may not be compatible. This mistake compromises the safety of your tire.

System Failure: The Risk of Mixing Brands 🧪 Each component in quality tire repair kits has a specific chemical job. The pre-buff cleaner prepares the tire surface. The vulcanizing fluid starts a chemical reaction with the patch. When you mix brands, you risk:

- Poor Adhesion: The cement may not bond correctly to the patch, creating a weak seal on the tire.

- Incomplete Curing: The chemical reaction might not finish, leaving the repair soft and prone to leaks.

- Liner Damage: A harsh, mismatched solvent could damage the inner liner of the tire.

A failed repair puts your tire at risk for a blowout. You must use a matched system for every tire repair. Reputable manufacturers engineer their products for perfect compatibility. This ensures a strong, permanent bond for your tire.

| System Type | Adhesion Quality | Repair Reliability | Tire Safety |

|---|---|---|---|

| Mixed Brands | Unpredictable | Low | Compromised |

| Complete System | Excellent | High | Maintained |

The best way to avoid this problem is to use complete tire repair kits from a single, trusted source. Companies like SUNSOUL provide end-to-end solutions. Their tire repair kits contain components that are all designed and tested to work together flawlessly. This guarantees the chemical synergy needed for a durable repair. Using one of their tire repair kits removes all guesswork. You can be confident that every step of the process contributes to a safe and lasting fix for your tire. A proper repair protects your tire investment.

Your tire’s longevity depends on a methodical repair process, not a quick fix. A successful tire repair for your tire requires attention to detail. You ensure a lasting solution for your tire when you follow the right steps.

Key Takeaways for a Lasting Repair 🔑

- You must choose the correct tire patch and size for the specific tire damage.

- A quality repair extends the life of your tire.

- This proper repair enhances your safety and keeps your truck efficient.

FAQ

Can I repair a tire sidewall?

No, you should never repair a tire sidewall. The sidewall flexes constantly and a repair cannot hold safely. Any damage to the sidewall means you must replace the tire. Even the best tire repair kits are not designed for this type of tire damage. Your safety depends on a new tire.

Is a tire plug a permanent repair?

A simple plug is only a temporary fix for a flat tire. For a permanent repair, you need a combination patch-plug unit. Quality tire repair kits include these units. They seal the inner liner of the tire and fill the puncture path, making your tire safe for the road.

Why must I use a complete repair system?

You should always use components from the same brand. Tire repair kits are designed as a system. The cleaner, cement, and patch in good tire repair kits work together chemically. Mixing brands can cause the repair to fail, putting your tire at risk. Use complete tire repair kits.

What should I look for in good tire repair kits?

Good tire repair kits contain everything for a proper repair. Look for tire repair kits with combination patch-plugs and a strong chemical cement. The best tire repair kits also include preparation tools. High-quality tire repair kits ensure a durable fix for your flat tire.