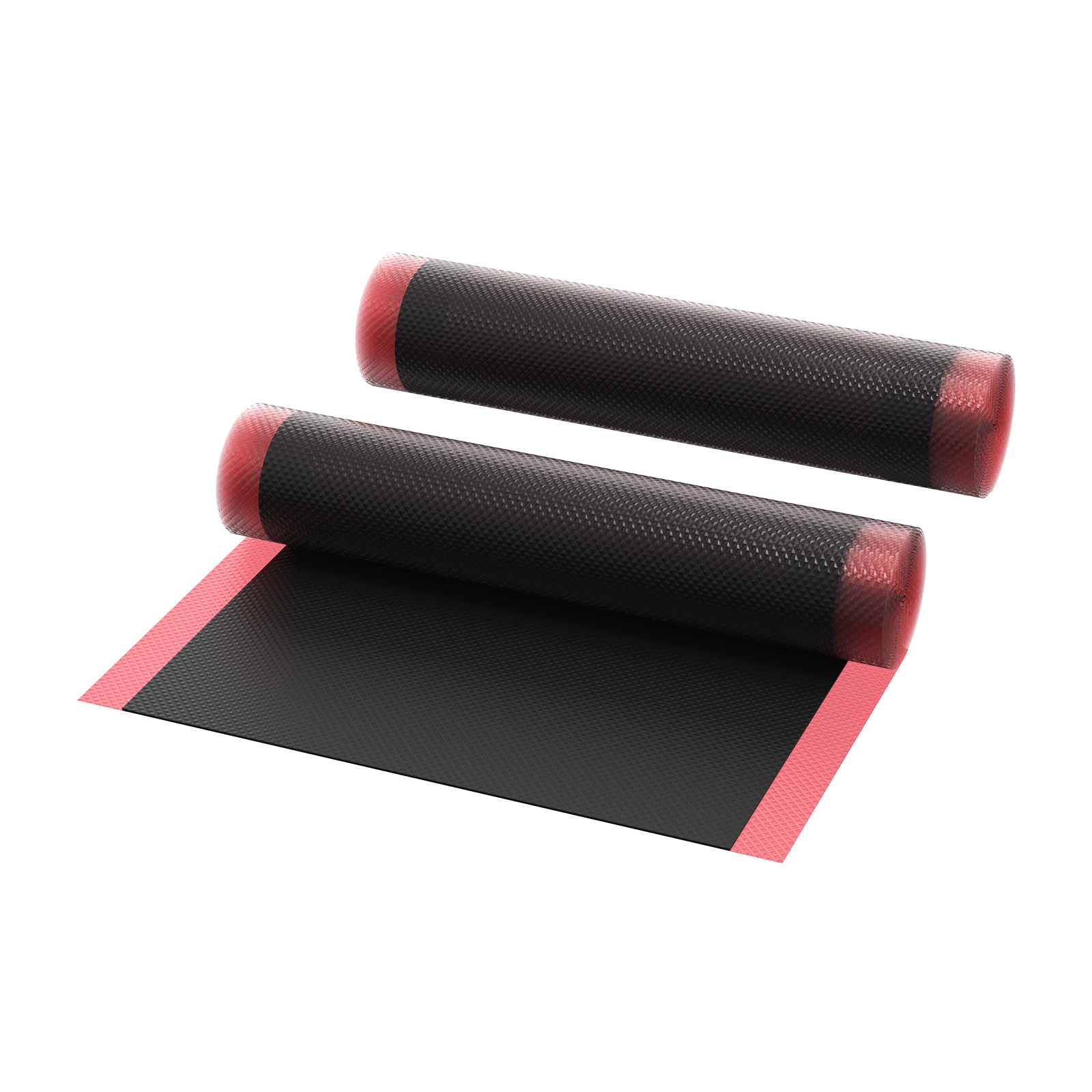

heavy duty tire patches

Heavy duty tire patches are durable repair solutions designed for significant punctures or damage in tires subjected to extreme stress, such as those on trucks, agricultural machinery, or off-road vehicles.

SUNSOUL implements strict supervision and quality management, and conducts 100% quality inspection during and after production through the QC system. The repurchase rate of heavy duty tire patches is as high as 99%.

SUNSOUL is a professional heavy duty tire patch manufacturer in China. We welcome more partners to become SUNSOUL dealers!

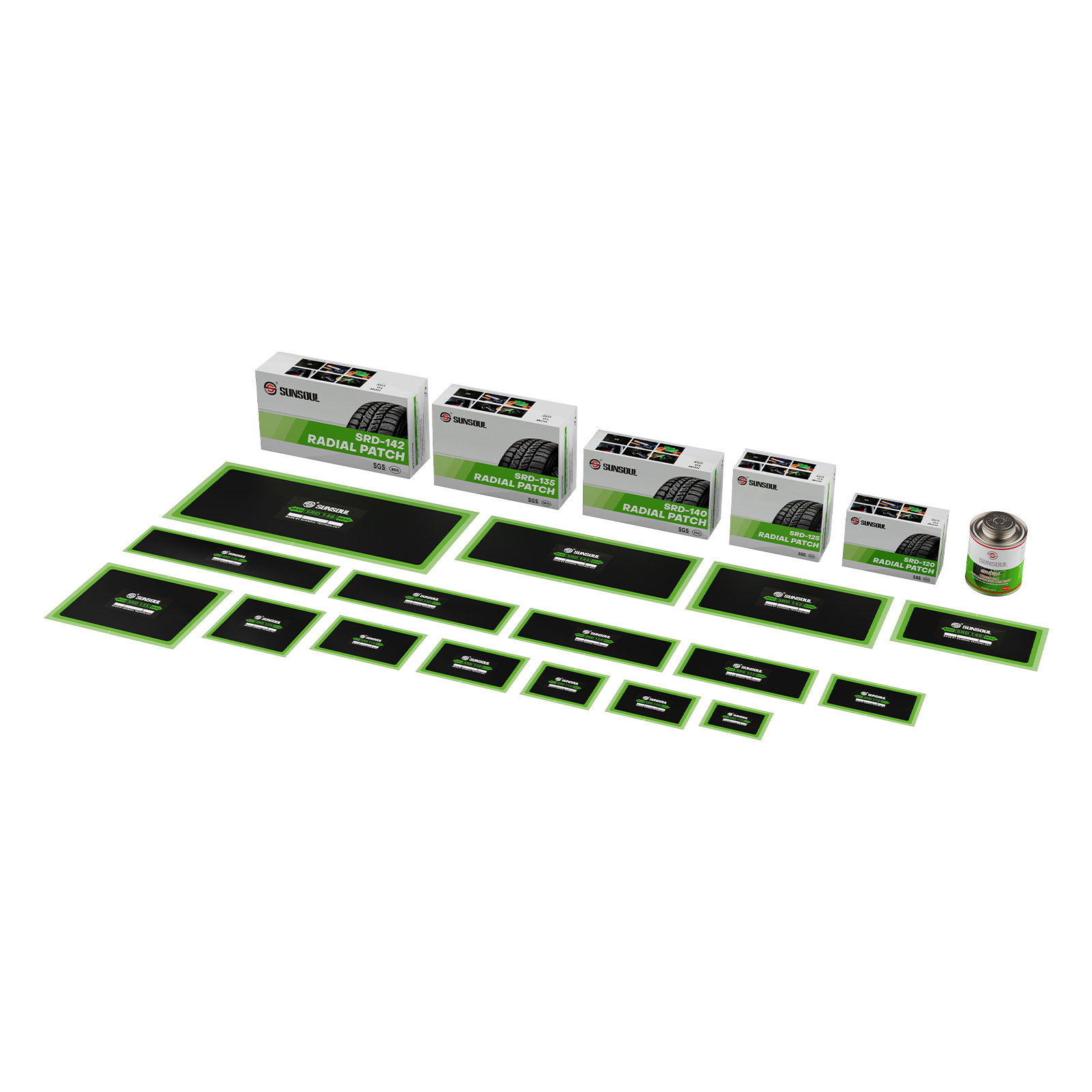

SUNSOUL Heavy Duty Tire Patch

SUNSOUL has a professional production factory, with a monthly output of more than 2 million heavy truck tire patches. Hot selling products include heavy duty truck tire patch kit, large tire patch, large tire plugs ect.

SUNSOUL CUSTOMER SAID

VAN

fast shipping, nice kit!

Extremely impressed with this purchase! it arrived even sooner than expected. The packaging was secure and professional. While I haven't had the chance to test yet, the initial quality far exceeds my expectations. Will definitely update this review after thorough use

irishcowboy

Good value

So much better than the old booger plugs, these get it sealed up for good. The metal rod is a huge help in pulling them through the hole. Good adhesion and easy to use. I tried one on a scrap tire. I get nails all the time, can't wait to try it out next time, I'll update my review when I have more experience on how long they hold up.

Michael D.

New product solution for me

I really like the design of this because it seems to mix the typical plug style and inner tire repair. This is cool because it has the durability of an internal repair, but it also has the plug that fills the gap on some tires with a fairly good sized chunk missing. I used this to repair a lawnmower tire that than been punctured with a good size piece of wire. Plugs just weren't filling the space well and sealing. This did the trick sealing inside.

SUNSOUL-trusted partner for heavy truck tire repair

With more than 20 years of production experience

The company is located in Ningbo, China, with convenient transportation

Integrating R&D, production, sales and services

Products are exported to more than 65 countries

Provide customers with 24-hour service before and after sales

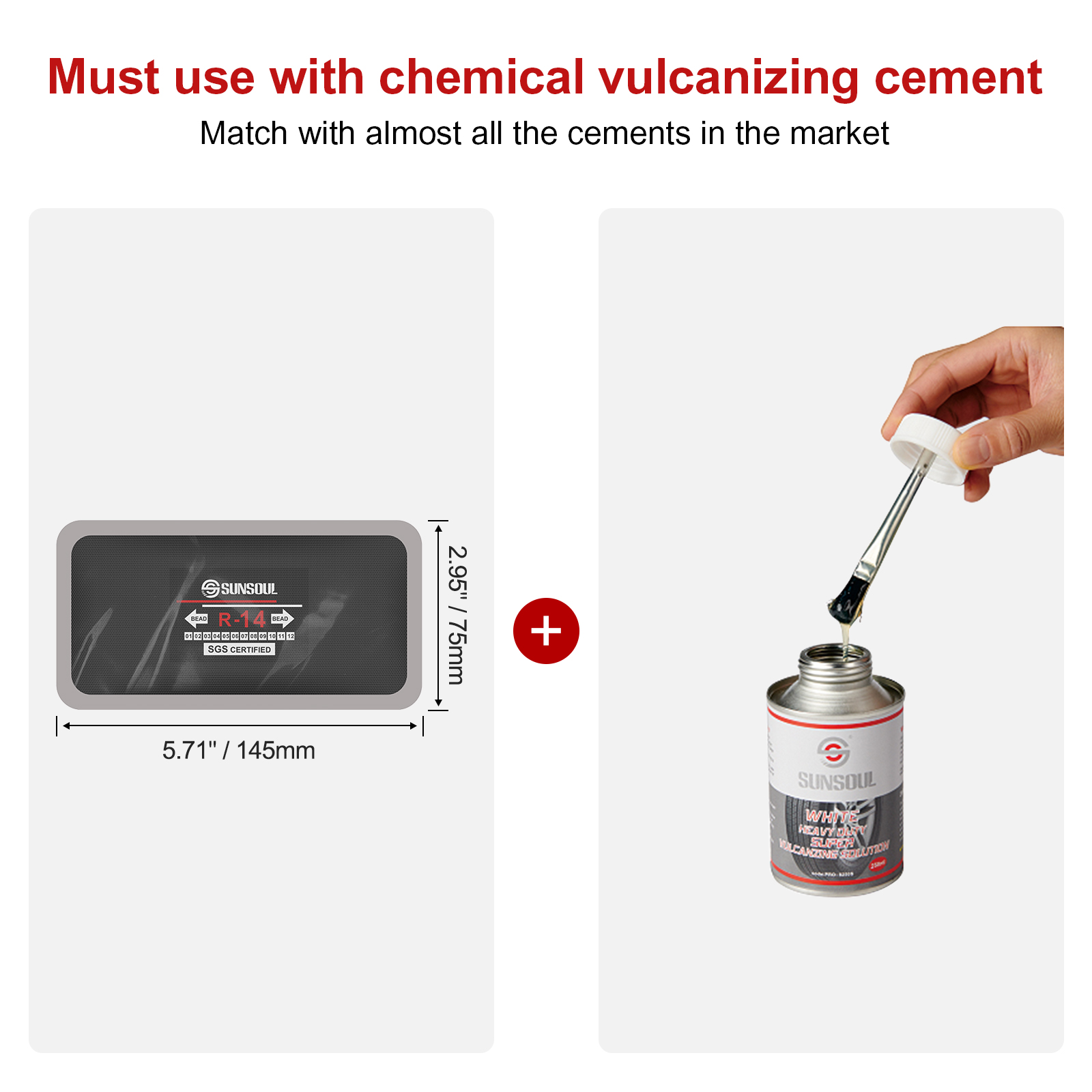

Heavy Duty Tire Patch Material

Rubber

Natural rubber: Has excellent elasticity and durability, often used in heavy duty tire patches. Able to withstand high temperatures and pressures.

Synthetic rubber: Commonly used for its wear and ageing resistance, suitable for all types of tires.

Bonding Materials

Vulcanized Adhesives: Used with vulcanizing tire patch, these adhesives are able to form a strong chemical bond between the patch and the tire.

Self-adhesive back: Simplifying the application process. This adhesive is usually designed to withstand high pressure and temperature.

Butyl rubber

This synthetic rubber is known for its excellent airtightness, making it suitable for heavy duty tire patches that need to maintain air pressure.

Vulcanized rubber

Rubber that has been chemically treated to increase its strength and elasticity. Vulcanizing rubber patch is usually used for more permanent repairs and bond well to the tire material.

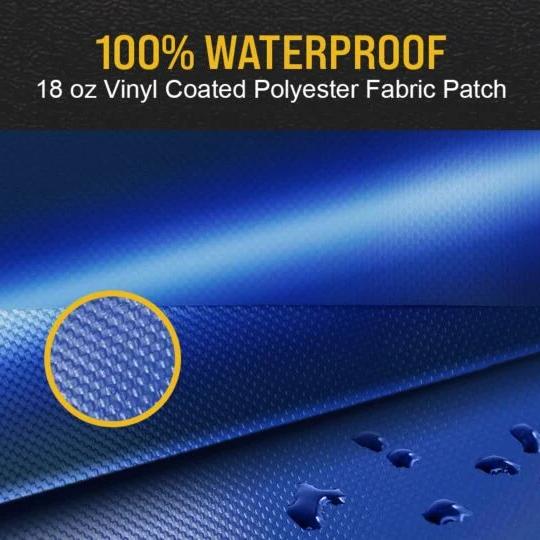

Polyester fabric

Some heavy duty tire patches use polyester fabric as a reinforcement for added strength. This material can help reinforce the patch and improve durability, especially in high-stress areas.

Composite Materials

Some heavy duty tire patches may use a combination of rubber and fabric for added strength and flexibility. These composite patches can provide a strong solution for all types of tire damage.

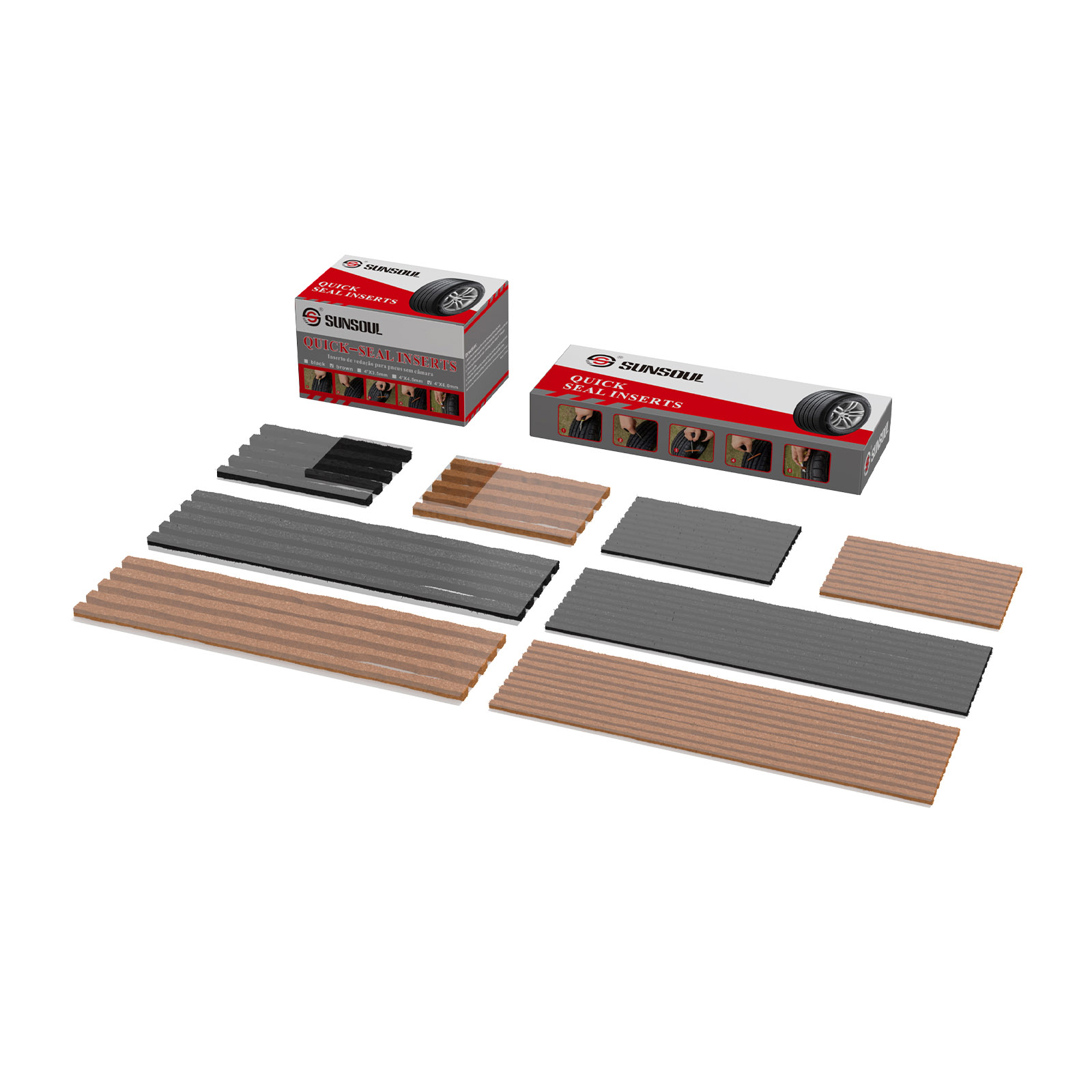

Heavy Duty Tire Patch Solutions

Trucks/commercial vehicles (e.g., vans, buses)

Common faults:

Large punctures (nails, metal fragments)

Tread wear or delamination (due to long-term high loads)

Applicable heavy duty tire repair kit solutions:

Strip-patch combination: repair punctures in the central area of the tread.

Vulcanized patch: for damage to the shoulder or seam, heat vulcanization is required to ensure firmness.

Limitations:

Tires need to be replaced when sidewall damage exceeds 6mm or carcass cord breaks.

Agricultural machinery (e.g., excavators, tractors)

Common faults:

Large tread tears (stones, sharp objects)

Inner liner damage under low-speed and high-pressure environments

Applicable heavy duty tire patch kit solutions:

Reinforced vulcanized patch: with metal mesh or fiber layer, repairs large holes (≤12mm).

Cold vulcanized quick patch: for emergency field repairs, no heating equipment required.

Off-road vehicles/SUVs

Common faults:

Sidewall scratches (rocks, branches)

Irregular punctures on the tread

Applicable heavy truck tire repair solutions:

Flexible radial patch: Adapts to frequent bending of tires.

Sidewall emergency patch (temporary use only): Some brands provide sidewall repair kits, but you need to drive at low speeds and replace the tires as soon as possible.

Ordinary sedans/family cars

Common faults:

Small punctures (nails, screws)

Local wear on the tread

Applicable heavy duty tire patch kit solutions:

Standard insert patch: Applicable to small holes in the center of the tread (≤6mm).

Limitations:

The sidewalls of sedan tires are thin and sidewall damage cannot be repaired!

SUNSOUL vs. Other Brands

Sunsoul core advantages

The best partner for small and medium-sized vehicles:

Sunsoul tire patches are mainly used for bicycles, motorcycles, cars, trucks, agricultural bulldozers, etc.

High cost performance:

The price is only 1/3-1/2 of rema, and compared with other brands, it can provide high-quality tire patches at a more favorable price.

Simple operation:

No heating equipment is required, and the glue has a wider adaptability (-40°C–120°C)

Glue pre-coating design, 10 minutes quick repair.

Long-term repair:

Provide long-term repair solutions, taking into account emergency and regular needs.

Other brands

REMA

Expensive, requires professional equipment and training.

TECH

Glue fails at low temperatures, and the kit price is high.

3M

For temporary use only, cannot replace regular patches.

heavy duty tire patches FAQ

Can you patch a radial tire with heavy duty tire patches?

Yes, you can repair a radial tire with heavy duty tire patches, but only under specific conditions and by following industry-approved guidelines.

When Is It Safe to Patch a Radial Tire with Heavy Duty Tire Patches?

Repairable Areas:

Tread center, Punctures must be ≥1.5 inches away from the sidewall.

Puncture Size:

Maximum 6–12 mm diameter.

Tire Condition:

No internal damage, Tread depth must be ≥2/32 inch.

What are the shipping and storage requirements for heavy duty tire patches?

Transportation requirements

1. Packaging protection

Sealed and moisture-proof: Use waterproof and dustproof sealed packaging (such as aluminum foil bags or vacuum packaging) to prevent glue from volatilizing or becoming ineffective due to moisture.

Buffering material: Fill the package with foam or bubble film to prevent the heavy duty tire patches from deforming due to extrusion.

Outer box label: Mark “”fragile””, “”anti-pressure””, “”light-proof”” and other labels to avoid stacking too heavy or exposing to extreme environments.

2. Temperature control

Avoid high temperature: The transportation temperature is recommended to be controlled at 10°C–30°C to prevent the glue from curing prematurely or softening and sticking.

Antifreeze protection: Below 0°C may cause the rubber to harden and crack, and an insulated box is required (especially for winter transportation).

3. Anti-chemical pollution

Keep away from oils, solvents or other corrosive chemicals to prevent degradation of heavy duty tire patches materials.

Storage requirements

1. Environmental conditions

Temperature: The optimal storage temperature is 15°C–25°C.

Humidity: Keep relative humidity at 50%–60%.

Avoid light: Store in a cool place and avoid direct sunlight.

2. Packaging management

Sealed storage: Unused heavy duty tire patches must be kept sealed in the original packaging to prevent glue oxidation or contamination.

Isolation storage: Store away from sharp tools and chemicals to avoid packaging damage.

3. Stacking and placement

Store flat, with a stacking height of no more than 5 layers to prevent the lower layer of patches from being compressed and deformed.

Use shelves or pallets to avoid direct contact with the ground (moisture-proof and insect-proof).

4. Expiration date management

Check the production date and follow the “”first in, first out”” principle to avoid expired use.

The shelf life of unopened patches is usually 2–3 years, and they must be used as soon as possible after opening.