Hot patch tire repair is a vulcanization process. It uses heat and pressure to bond a patch to your tire, creating a permanent repair. This method offers superior durability for your tire, making it the gold standard for long-term tire repair. A reliable repair is critical for every tire on your vehicle.

Did You Know? Each year, over 11,000 crashes in the U.S. are tire-related. Common causes for tire damage include:

- Punctures and cuts

- Road hazards

- Improper tire air pressure

Choosing a quality patch ensures a safe, seamless seal for your tire.

What Makes Hot Patch Tire Repair the Superior Choice?

You might wonder what sets a hot patch tire repair apart from a quick, temporary fix. The answer lies in a powerful chemical process and its incredible results for your tire’s durability and longevity. This method creates a bond that is fundamentally stronger and more reliable, making it the best choice for a permanent tire repair.

The Science of Vulcanization

Vulcanization is the chemical process that gives rubber its strength and elasticity. When you apply a hot patch, you are not just gluing it on; you are chemically remolding the tire itself.

Here is how it works:

- Vulcanization is a chemical process that improves the elastic properties of rubber.

- During vulcanization, rubber molecules in the tire and the patch react with each other.

- Sulfur compounds in the patch cross-link these rubber molecules.

- This cross-linking creates a permanent, unified structure.

Essentially, chains of sulfur atoms build bridges between the rubber polymers of your tire and the patch. This transforms two separate pieces into one seamless piece of rubber. The type of vulcanization system used can even fine-tune the tire’s final properties.

| Vulcanization System | Accelerator/Sulfur Ratio (A/S) | Primary Crosslink Type | Tensile Strength | Resistance to Flexing |

|---|---|---|---|---|

| Conventional (CV) | Lower | Poly-sulfidic (many sulfur atoms) | High | Low |

| Efficient (EV) | Higher | Mono/Di-sulfidic (few sulfur atoms) | Lower | Higher |

| Semi-Efficient (SEV) | Intermediate | Intermediate | Intermediate | Intermediate |

This table shows how different chemical mixtures create different strengths. For a tire, a balanced approach ensures both high strength and good flexibility, contributing to its overall longevity.

Durability vs. Cold Patching

When you compare hot and cold tire patching methods, the difference in durability and longevity is significant. A cold patch is a temporary solution, while a hot patch is designed to last for the remaining life of the tire.

Note: Laboratory tests show that the tensile strength of cold repairs is significantly lower than that of hot repairs. A hot repair can withstand compressive forces of 1,500-3,000 PSI, while a cold patch often fails under 800 PSI.

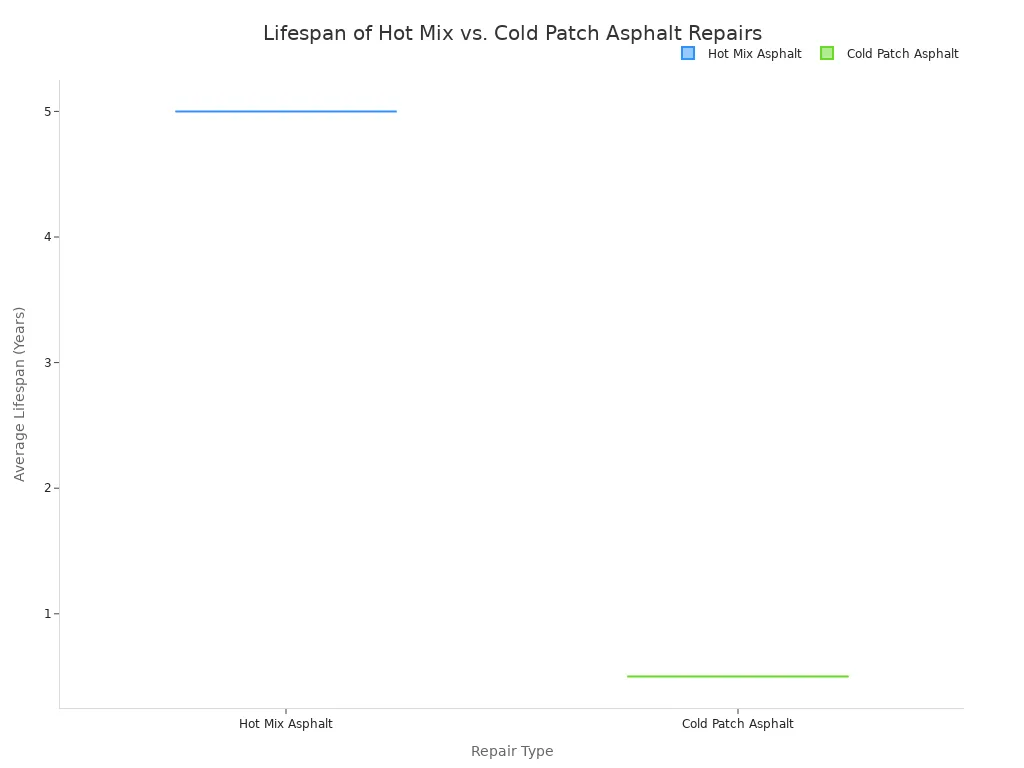

This strength difference has real-world consequences. A cold patch might only last 6 to 12 months before it fails, especially under heavy traffic or in extreme weather. In contrast, a properly applied hot patch can last for 5 to 8 years or even longer, offering superior longevity.

This chart clearly illustrates the vast gap in expected lifespan. A hot repair can handle over 20,000 vehicles daily, whereas a cold patch may begin to fail within weeks in high-traffic areas. For a dependable repair, the choice is clear.

Creating a Permanent Air Seal

The goal of any tire patching is to create a perfect, airtight seal. The hot patch method excels at this by using a combination of controlled heat and pressure. This process ensures the ultimate longevity of your tire.

A vulcanizing machine heats the patch and the surrounding tire area to an optimal temperature, typically between 145–175°C (293–347°F). This heat activates the chemical reaction. At the same time, the machine applies firm pressure. This pressure is critical for several reasons:

- It ensures the melted rubber flows uniformly.

- It forces the patch to bond completely with the tire surface.

- It eliminates any trapped air bubbles that could cause a slow leak.

The result is a seamless, permanent bond that is just as strong as the original tire. This robust seal prevents air from escaping, ensuring your tire remains properly inflated and safe to drive on. This reliable method of tire patching gives you peace of mind and maximizes the tire’s service life.

A Step-by-Step Guide to Flawless Hot Patching

A successful hot patch tire repair depends on precision and following the correct steps. This guide breaks down the tire repair process into manageable stages. You can achieve a permanent, safe fix for your flat tire by following these professional guidelines. Each step, from the initial inspection to the final cure, is critical for a lasting repair.

Step 1: Puncture Inspection and Tire Preparation

Before you begin any repair, you must perform a thorough tire inspection. This initial inspection determines if your flat tire is a candidate for a safe repair. Not all damage can be fixed. The U.S. Tire Manufacturers Association (USTMA) provides clear tire repair guidelines for this purpose.

Your tire is likely repairable only if it meets these criteria:

- Puncture Size: The injury must be no larger than 1/4 inch (6mm) in diameter.

- Puncture Location: The damage must be within the crown or tread area of the tire. You cannot repair punctures in the shoulder or sidewall.

If the damage to your flat tire fits within these guidelines, you can proceed with the tire repair. The next phase is preparing the inner surface of the tire. A clean, properly prepared surface is essential for the patch to bond correctly.

Pro Tip: Follow this tire repair process for a perfect surface. First, outline an area about a half-inch larger than your patch. Use a low-speed buffer (max 5,000 rpm) to create a textured surface. Be careful not to damage the inner liner of the tire. Next, vacuum all the buffing dust away. Finally, clean the area with a proper fluid and let it dry completely.

Step 2: Applying Vulcanizing Cement

With the tire prepped, your next step is applying the vulcanizing cement. This special adhesive is more than just glue. It is a chemical compound designed to create a powerful bond during the hot patch tire repair.

The cement typically contains several key ingredients:

- Elastic Polymers: Natural rubber forms the base of the cement.

- Solvents: Chemicals like heptane or toluene keep the rubber in a liquid state for easy application.

- Accelerators: These compounds speed up the chemical vulcanization reaction when you apply heat.

You should apply a thin, even coat of the cement over the entire buffed area. Do not let it pool or drip. Allow the cement to air dry until it feels tacky to the touch. You should not use heat guns or compressed air to speed up this process, as it can compromise the chemical reaction. This patience ensures the strongest possible bond for your flat tire.

Step 3: Patch Placement and Curing

This final stage brings the repair together. You will place the patch and use a vulcanizer to cure it, creating a permanent seal. Careful execution here is critical for the success of the entire operation.

First, you must position the patch correctly over the prepared area. Press it down firmly from the center outward. This action removes any trapped air bubbles. Once the patch is in place, the tire is ready for the vulcanizing machine. The machine applies both heat and pressure, activating the cement and chemically bonding the patch to the tire.

To ensure a flawless result, you must avoid common mistakes. Following these guidelines will help you prevent a failed repair.

| Common Mistake | How to Avoid It |

|---|---|

| Improper Positioning | Use fabric markers for precise alignment. Double-check the placement before applying pressure. |

| Insufficient Pressure | Apply consistent, firm pressure to eliminate air bubbles and ensure the glue penetrates the tire fibers. |

| Incorrect Curing | Follow the manufacturer’s instructions for temperature and time. Do not rush the curing process. |

| Glue Seepage | Apply a thin, even layer of cement. Immediately wipe away any excess that squeezes out from the edges. |

After the curing cycle is complete, allow the tire to cool down completely. A final inspection of the patch ensures the edges are fully sealed and the repair is seamless. This last check confirms your flat is fixed and the tire is ready for service.

Step 4: Cooling and Final Inspection

You have reached the final and most critical stage of the tire repair process. After the vulcanizer completes its cycle, you must allow the tire to cool down naturally. Do not try to speed this up with water or compressed air. This cooling period allows the new rubber bond to set and stabilize, ensuring maximum strength and durability for the tire.

Once the tire is completely cool to the touch, you can begin the final inspection. This step verifies that your work meets safety guidelines and creates a permanent seal. A thorough tire inspection is not just a suggestion; it is a mandatory part of a professional repair. Follow these tire repair guidelines to confirm a successful bond.

- Press down on the patch firmly. Use a stitching tool to work out any remaining air bubbles, moving from the center to the edges.

- Examine the patch edges closely. They must lie completely flat against the tire. If you see any lifted areas, you must re-press them.

- Apply a thin layer of repair sealer around the patch edges. This provides an extra layer of protection against future leaks.

- Trim any plug stem so it is flush with the tire tread if you used a combination unit.

- Inflate the tire to its recommended pressure. Check for leaks by spraying a soapy water solution on the repair. If you see bubbles, the seal is not complete.

A proper final inspection ensures the puncture is completely filled and the inner liner is sealed to prevent air loss. If you find a leak, you must remove the tire from the wheel for a complete re-inspection of your work. This careful tire repair process guarantees the safety of the tire.

Pro Tip: Your responsibility does not end after the initial inspection. You should monitor the repaired tire over time to ensure its long-term integrity. Following these monitoring guidelines will help you catch any potential issues early.

| Monitoring Step | What to Look For | How Often |

|---|---|---|

| Tire Pressure Check | Consistent air pressure | Weekly |

| Patch Inspection | No bubbles or cracks | Monthly |

| Professional Review | Secure patch, safe tire | After 200-300 miles |

| Tread Wear Monitoring | Even wear, no soft spots | Every oil change |

Completing this final step of the tire repair process with attention to detail is essential. Following these tire repair guidelines ensures your repair is safe, reliable, and will last for the remaining life of the tire.

Essential Tools for Professional Tire Repair

To perform a professional hot patch tire repair, you need more than just skill. You need the right equipment. Using high-quality tools ensures the safety and longevity of every tire repair. The right gear protects you and guarantees a durable repair. This commitment to professional tools is essential for tire repair safety.

The Role of a Quality Vulcanizer

A quality vulcanizer is the heart of any professional hot patch operation. This machine provides the controlled heat and pressure needed to create a permanent bond. A basic machine might get the job done, but a professional model offers precision, efficiency, and enhanced safety. Modern vulcanizers come with features that streamline the repair process and improve results. Investing in a good machine is an investment in the safety of every tire you service.

Note: Professional vulcanizers offer advanced controls and safety certifications that are critical for reliable performance. Choosing the right model depends on your workload and the types of tire you handle.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Manual operation | Semi-automatic | Fully automatic |

| Max Load Capacity | 1500 kg | 2000 kg | 2500 kg |

| Safety Certifications | ISO 9001 | ISO 9001 + CE | ISO 9001 + CE + OSHA |

| Cycle Time | 12 mins/tire | 10 mins/tire | 8 mins/tire |

These features ensure every tire receives a consistent and safe repair, which is a cornerstone of professional tire repair.

Choosing the Right Hot Patches

The patch you choose is just as critical as the vulcanizer. A superior patch creates a stronger, more reliable seal. SUNSOUL is a leading manufacturer, producing over two million tire patches each month. Their products are trusted in more than 60 countries for their exceptional quality.

SUNSOUL patches are known for their:

- Excellent Thickness: Provides a robust and durable repair.

- Strong Adhesion: Creates a powerful bond with the tire.

- Smart Design: A round shape helps prevent the patch edges from peeling over time.

Their commitment to quality makes them a top choice for any professional seeking a dependable tire solution. Using a high-quality patch is a key part of ensuring the long-term safety of the tire.

Essential Safety and Prep Gear

Proper preparation and personal safety are non-negotiable. Before you even turn on the vulcanizer, you need the right gear to prepare the tire and protect yourself. Having these tools on hand makes the process smoother and safer. Your safety is paramount during any work on a tire.

Here is a checklist of essential gear for your professional toolkit:

- Safety Glasses and Gloves: Protect your eyes and hands from dust and heat.

- Low-Speed Buffer: Creates the ideal texture on the tire’s inner liner without causing damage.

- Tire Scraper: Helps clean the puncture area thoroughly.

- Buffing Dust Vacuum: Removes all debris for a clean bonding surface.

- Repair Sealer: Adds an extra layer of protection around the patch edges.

Using the correct gear ensures your personal safety and the structural integrity of the tire.

Why SUNSOUL Is a Leader in Tire Patching Solutions

When you choose your repair materials, you want a brand that delivers on its promises. SUNSOUL stands out as a global leader in the tire patching industry. The company provides reliable products and strong support for professionals like you. Their commitment to excellence makes them a trusted partner for any tire service business.

Unmatched Production and Global Reach

SUNSOUL operates on a massive scale. The company produces over two million tire patches every month. This high capacity ensures a stable supply for partners around the world. You can find their products in more than 60 countries. This global trust means you can depend on them for consistent access to quality tire repair materials.

Superior Patch Quality and Reliability

The quality of your patch directly impacts the safety of every tire repair. SUNSOUL products adhere to strict USA standards for performance. This focus on quality ensures every tire patching job you perform is reliable. You can trust their patches because they meet rigorous international certifications and testing protocols.

Quality You Can Count On SUNSOUL’s manufacturing process includes:

- ISO 9001 Certification: Guarantees consistent production quality.

- Safety Compliance: Products are DOT compliant for road safety and CE marked for European markets.

- Comprehensive Testing: Each patch undergoes pressure tests, water immersion tests, and durability simulations to ensure a perfect seal on the tire.

This dedication to quality means you are using a patch that creates a strong, permanent bond for every tire.

Comprehensive Support for Partners

SUNSOUL believes in building strong partnerships. They offer more than just a great product for your tire. They provide the resources you need to succeed in the tire patching business. This support empowers you to offer the best service to your customers.

- Professional Training: You get access to free technical training, both online and on-site, covering product use and repair techniques.

- Technical Empowerment: For complex cases, SUNSOUL can dispatch engineers to provide expert assistance with a difficult tire repair.

- Logistics Guidance: The company helps you manage your inventory effectively.

- Marketing Support: You receive co-branding materials and marketing tactics to help grow your business.

This comprehensive support system makes SUNSOUL a true partner in your success.

When Is Hot Patching the Right Call for Your Tire?

You need to know when a hot patch is the best choice for your flat tire. The right tire patching method depends on your vehicle and your goals. Certain situations demand the strength and longevity that only a vulcanized repair can provide. A flat tire on a heavy truck is very different from a flat on a small car.

High-Performance and Heavy-Load Vehicles

Your high-performance car or heavy-duty truck puts immense stress on every tire. These vehicles generate significant heat and force during operation. A simple plug or cold patch might fail under these conditions. A strong repair is essential for the safety and longevity of your tire. When you have a flat, you need a solution that restores the tire’s original strength. This type of tire patching ensures the tire can handle high speeds and heavy loads safely. The longevity of the tire is a top priority.

Important: For vehicles that carry heavy loads or travel at high speeds, a vulcanized repair is not just recommended—it is a critical safety measure for the tire.

Off-Road and Agricultural Tires

Off-road and farm vehicles operate in harsh environments. The tire constantly flexes and faces impacts from rocks, stumps, and debris. A temporary fix for a flat tire will not last long. The constant stress can easily cause a cold patch to peel or leak. You need a tire patching method that creates a seamless bond with the tire. This ensures the repair holds up against rough terrain, giving the tire maximum longevity. A flat in the middle of a field requires a dependable fix. The longevity of the tire is crucial for your work.

Seeking a Permanent, Long-Term Repair

You should choose a hot patch when your goal is a permanent repair. If you want to fix your flat tire once and maximize the tire’s lifespan, this is the best method. A hot patch tire repair chemically bonds to the tire, becoming part of it. This provides superior longevity for your flat tire. Other methods offer a temporary fix for a flat.

Consider your goal for the tire repair.

| Repair Goal | Recommended Method | Expected Lifespan |

|---|---|---|

| Get back on the road quickly | Cold Patch / Plug | Temporary (Months) |

| Restore tire integrity | Hot Patch | Permanent (Years) |

This choice ensures the tire remains safe and reliable for the rest of its service life.

The Future of Hot Patch Tire Repair in 2025

The world of hot patch tire repair is getting smarter and safer. As we look to 2025, new technologies are changing how you fix a tire. These advancements promise a stronger repair and better safety for every tire you service. The future focuses on improving materials, machines, and safety procedures.

Advanced Vulcanizing Compounds

The chemicals you use to repair a tire are becoming more advanced. Scientists are creating new formulas that make your repair stronger and more environmentally friendly. These innovations improve the overall safety and durability of the tire.

What’s New in 2025?

- Ozone Resistance: New compounds use special rubber (EPDM) to protect the tire from sun damage and cracking, boosting long-term safety.

- Greener Formulas: Companies are reducing harmful zinc in their mixtures, making the tire repair process better for the environment without losing strength.

- Stronger Bonds: Other formulas use special agents that prevent the tire from becoming weak during the heating process, ensuring a perfect bond and maximum safety.

Smart Vulcanizing Machines

Vulcanizing machines are no longer just simple heaters. New smart machines use technology to guarantee a perfect repair every time. This technology takes the guesswork out of the process, which is a huge step forward for tire repair safety. Many new models include intelligent systems that improve precision and efficiency. For example, some machines now use AI to spot defects in the tire in real-time. This increases the accuracy of your work and the safety of the final tire.

These smart features directly improve the quality and safety of your work on a tire:

- IoT Connectivity: You can monitor the machine from a phone or computer for better quality control.

- Precision Temperature Control: Advanced models hold a temperature with an accuracy of ±0.5°C, ensuring a perfect cure.

- Energy Savings: New heating systems can cut power use by up to 25%, saving you money.

Evolving Safety Protocols

New technology is making safety protocols better than ever. Smart machines reduce the chance of human error. This automation leads to a more consistent and reliable repair for every tire. When a machine controls the temperature and pressure perfectly, you get a safer outcome. This focus on technology is the future of safety in the tire industry. Following these evolving protocols is key to ensuring the highest level of safety for each tire. Your commitment to modern methods protects both you and your customers.

A hot patch tire repair offers the most durable repair for your tire. Your safety is paramount. Following best practices with a quality patch, like those from SUNSOUL, ensures the safety of your tire and maximizes its life. For ultimate safety with your tire, you have two choices for your safety.

Your Path to Tire Safety:

- Seek a professional service for this tire work.

- Invest in professional training and equipment for a DIY patch application.

This professional approach to your tire ensures total safety. A professional tire repair from tire repair professionals guarantees the safety of your tire. Your tire deserves this level of professional safety. This repair ensures tire safety.

FAQ

How much does a hot patch repair cost?

A hot patch repair typically costs between $40 and $75. This is higher than a temporary plug. The tire repair cost reflects the use of specialized equipment and the permanent nature of the fix. You get a durable, long-lasting repair that restores the tire’s integrity.

How long does a hot patch repair take?

A professional hot patch repair usually takes 45 to 60 minutes. This includes preparation, curing with the vulcanizer, and the essential cooling period. The cooling step is critical. It allows the chemical bond to set properly, ensuring a strong and permanent seal for your tire.

Can I perform a hot patch repair at home?

You should not attempt a hot patch repair at home without proper training. The process requires a vulcanizing machine and specific knowledge. For your safety, you should seek a professional service. Professionals have the right tools and expertise to ensure a safe, reliable repair.

Can you hot patch any type of tire?

Yes, you can hot patch most types of tires. This method is especially effective for tires on heavy-load, agricultural, and off-road vehicles. The strong, vulcanized bond holds up well under the extreme stress these tires face, ensuring maximum durability and safety.