radial tire patch

A flat piece of rubber called a radial tire patch is applied to the interior of a tire to fix damage. The term “radial” describes tires of the radial kind, which account for nearly all tires on the road today. To apply radial tyre patch, the tire must be taken off of the wheel and the car.

radial tire patch types

These are the most common type of patches used when repairing tires. They are made of rubber and are glued to the inside of the tire at the puncture. They are strong sealants and are suitable for most tread punctures.

Self-adhesive Patches

These patches come with an adhesive backing so they can be easily applied without the use of additional glue. They are typically used to repair small punctures in the tread area.

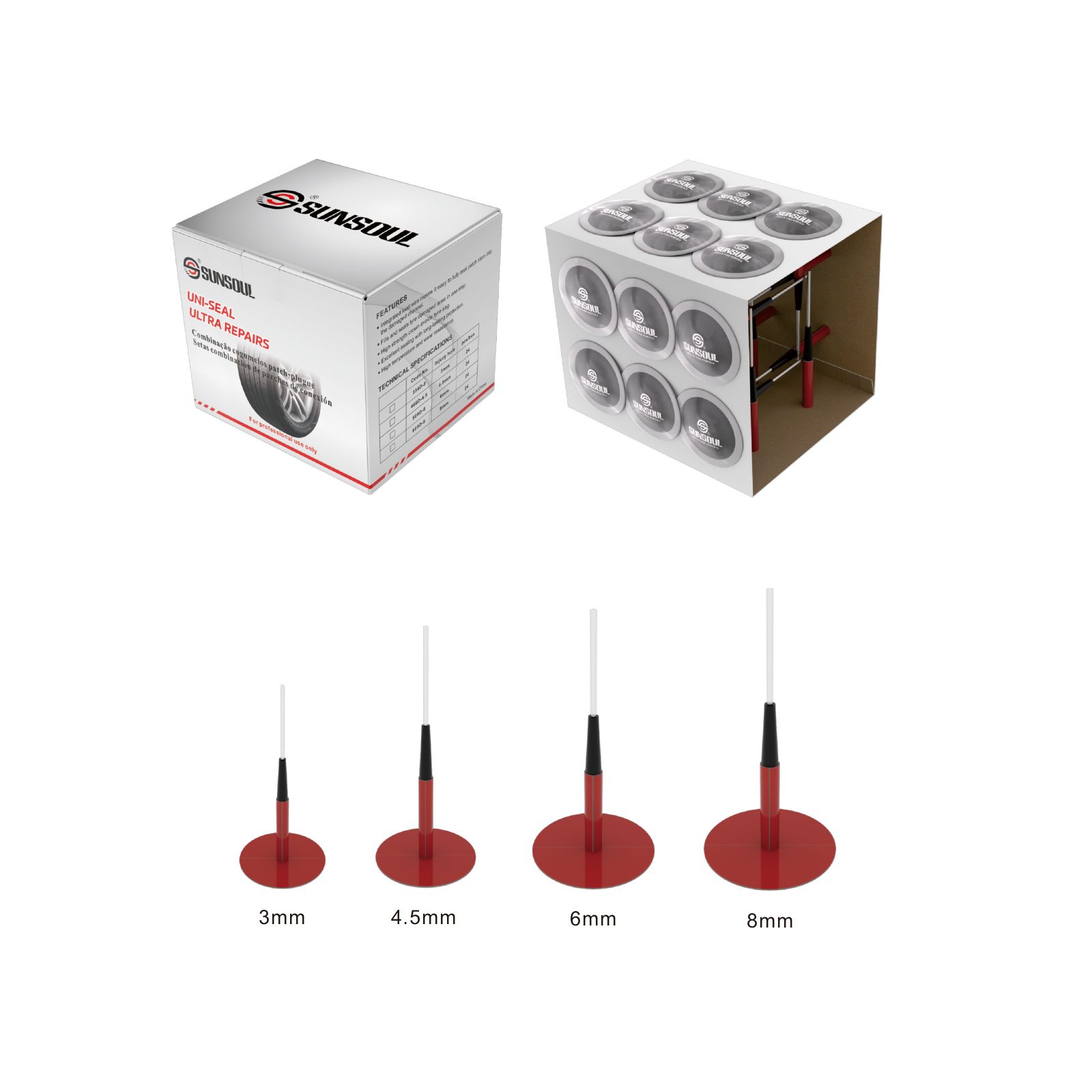

This tire repair method combines a plug and a tire patch. The rubber plug is inserted into the puncture from the outside, and the tire patch is attached to the inside of the tire. This method can be repaired more safely, especially for larger punctures.

Steel Belt Patches

These patches are designed for tires with steel belts. They are reinforced to withstand the stress of radial tire structure and can be used for more significant repairs.

Tread Patches

Designed to repair larger punctures or cuts in the tread area, these patches are larger and cover a larger area.

Radial Tire Patch Sidewall

Damage to the sidewall cannot usually be repaired, but there is radial tire patch sidewall designed specifically for minor punctures in the sidewall. However, best practice is usually to replace the tire if any significant damage to the sidewall occurs.

Radial Tire Patch VS Alternative Solution

When comparing radial repair patches to alternative solutions for tire repair, it’s important to consider the effectiveness, safety, and suitability of each method.

Radial Tire Patch

advantage:

Cost-Effective: Patching a tire is usually cheaper than replacing it, so it is an affordable option for minor repairs.

Quick fixes: Patches can usually be completed quickly, allowing services to be restored more quickly.

Sustainability: Repairing tires extends their life and reduces waste, which is better for the environment.

shortcoming:

Limited Repair Coverage: Not all damage can be repaired, especially if there is sidewall damage or the tire has severe wear or structural issues.

Safety Issue: Improperly repaired tires may cause blowouts or other failures, especially if the repair is improper or the damage is severe.

Alternative Solutions

Tire Replacement

advantage:

Ensure safety and reliability, especially in case of severe tire damage.

New tires come with a warranty and are designed to meet current safety standards.

shortcoming:

More expensive than repairing.

If old tires are not recycled properly, they go to waste.

advantage:

Temporary repair of small punctures without removing the tire.

Easy to use, driver can apply it.

shortcoming:

Generally considered a temporary solution; may not be effective for larger punctures or sidewall damage.

May complicate future repairs as sealant may interfere with patching.

Professional Repair Services

advantage:

Professional services can provide comprehensive assessments and repairs, including patching, plugging and even renovations.

shortcoming:

May be more expensive than DIY methods.

Radial Tire Plug VS Radial Tire Patch

Radial tire plug

A radial tire plug is a rubber or synthetic material that is inserted into the puncture from the outside of the tire. It is usually used to repair small punctures in the tread area.

advantage:

Quick Application: Tire plugs can be quickly applied without removing the tire from the wheel, making roadside repairs easy.

Cost-Effective: Usually cheaper than a full patching process, especially for minor punctures.

Immediate Use: After inserting the plug, the tire can usually be used immediately, depending on the manufacturer’s recommendations.

shortcoming:

Limited Repair Coverage: Plugs are generally only suitable for small punctures in the tread area and are not recommended for sidewall damage.

Temporary Solution: While plugs can provide a quick fix, they may not be as durable as patches, especially under high-speed conditions or heavy loads.

Possibility of Leakage: If not installed correctly, the plug may cause air leaks over time.

Radial tire patch

It is often used for repairs that require a safer, more permanent solution.

advantage:

Stronger Repairs: Patches provide a more robust and durable repair, especially for larger punctures or when used in conjunction with plugs.

Long-term Solution: When used properly, patching can extend the life of your tire and is generally considered a more permanent repair.

Full Coverage: The patch can cover a larger area of damage and is suitable for all types of punctures.

shortcoming:

More Time Consuming: Patching requires removing the tire from the wheel and may take longer than simply inserting a plug.

Skills Required: Using the patch correctly requires a certain amount of skill and knowledge, so it is not suitable for DIY repairs if you don’t have experience.

Cost: Patching can be more expensive than plugging, especially if done by a professional.

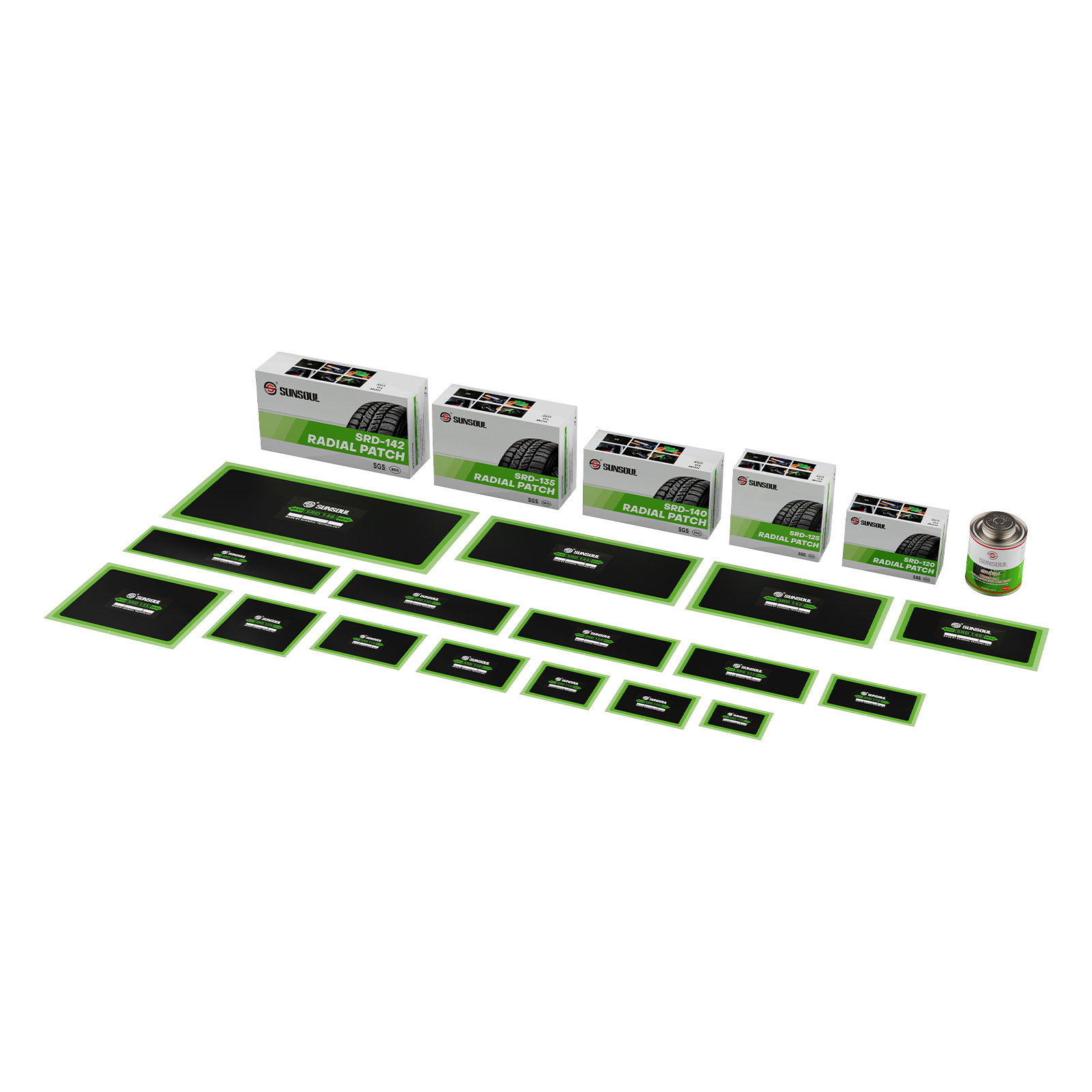

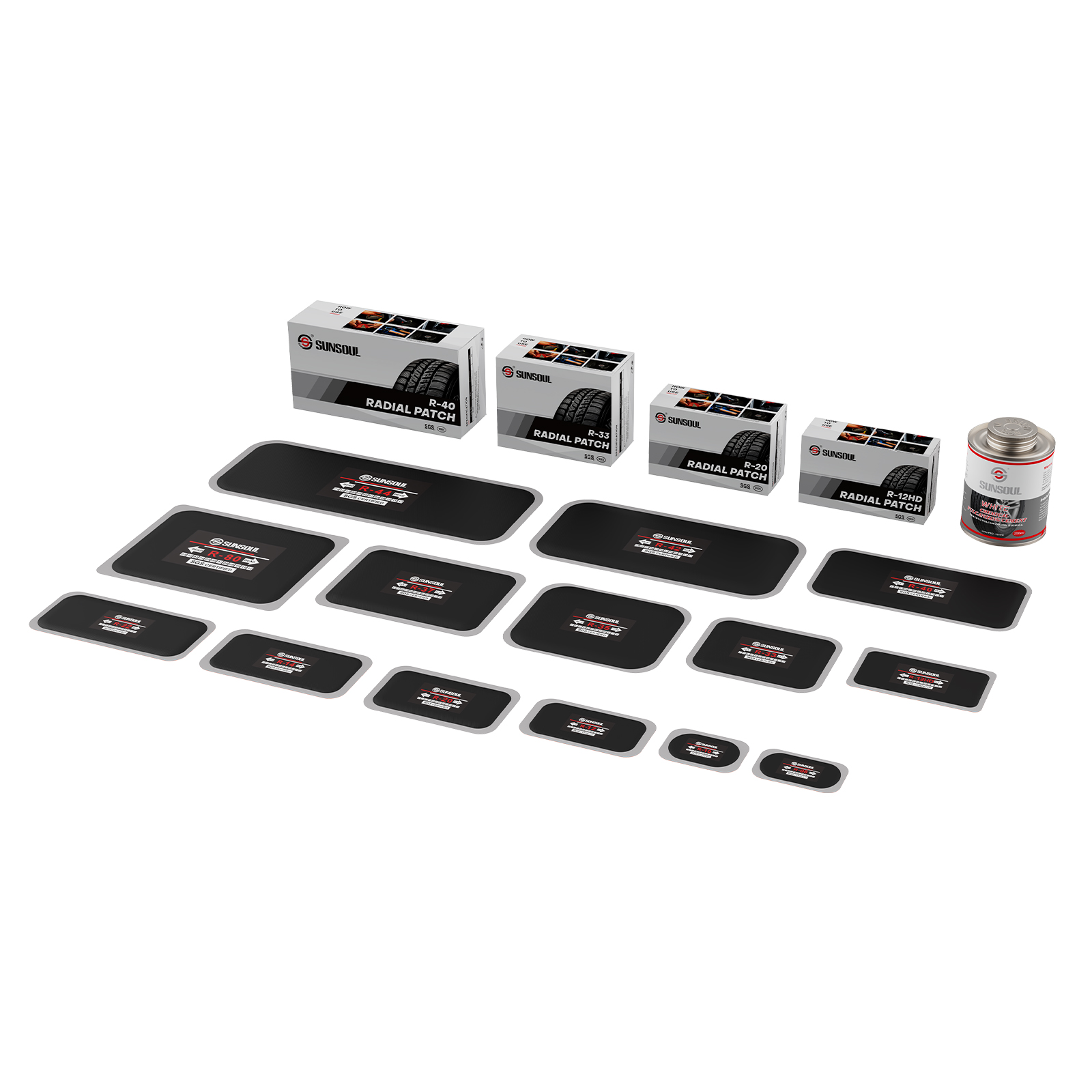

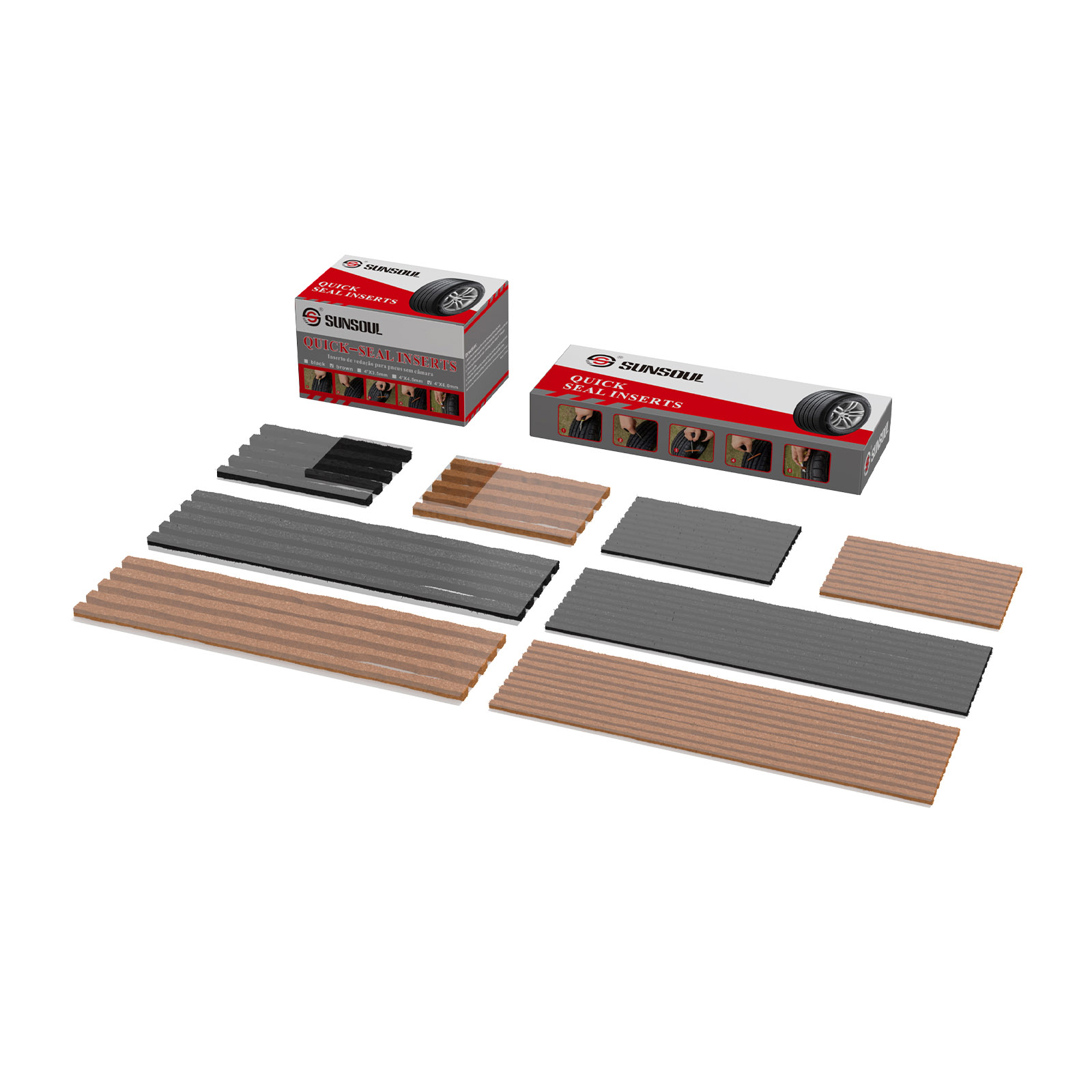

radial tire patch kit We Provide

Radial tire repair kit is tools and materials designed specifically for repairing punctured radial tires. These kits typically include everything needed to perform a tire repair, making them easy for professional tire technicians and DIY enthusiasts to use.

Components of a Radial Tire Repair Kit

Radial Tire Repair Patches:

Various sizes and types of rubber patches designed for radial tires. These may include self-adhesive patches or patches that require the use of an adhesive.

Adhesive:

A strong rubber glue or adhesive used to bond the patch to the tire. Some kits may include a specific type of adhesive recommended for tire repair.

File:

Tool used to roughen the surface around a tyre puncture to ensure better adhesion of the repair.

Insert tool:

If a radial tire plug is included in the kit, use the insertion tool to insert the plug into the puncture from the outside of the tire.

Cleaning tools:

Use an item such as a brush or rag to clean the area around the puncture before applying the patch.

Description:

Step-by-step instructions on how to properly use the kit for an effective tire repair.

Types of Radial Tire Repair Kit

Basic Repair Kit:

These kits usually include some patches, adhesives, and basic tools for simple repairs.

Comprehensive Kit:

A more extensive kit may include various patch sizes, multiple tools, and additional materials for more complex repairs.

Emergency Kit:

These kits are designed for roadside repairs and may include quick-fix solutions like tire sealant or plugs, as well as basic patching materials.

Professional Kit:

These kits used by tire shops usually contain a wider range of patches and tools to perform a wider range of repairs.

radial tire patch Q&A

How to repair a radial tire with a radial tyre patch?

Check tires:

Locate the damage to ensure it is in the tread area of the tire and not the sidewall. Repairs are not usually recommended for sidewall damage.

Removing the tire:

If necessary, use a tire lever to remove the tire from the rim. Make sure you do this in a safe environment.

Cleaning the damaged area:

Clean the damaged area with a detergent to remove any dirt, grease or other impurities. Make sure the surface is dry.

Roughen the surface:

Use sandpaper or a sanding tool to gently roughen the damaged area to increase adhesion of the patch.

Apply glue:

Apply glue evenly over the roughened area, following the instructions on the glue’s instructions. Allow the glue to dry slightly until it becomes tacky.

Apply the patch:

Carefully place the patch over the glue, making sure to completely cover the damaged area. Press the patch with your hands to make sure there are no bubbles and that the patch fits tightly against the tire surface.

Curing:

Allow the patch to cure for the appropriate amount of time, according to the glue’s instructions. Some glues may take longer to reach optimal strength.

Reinstall the tire:

If the tire has been removed, follow the correct procedure to reinstall it on the rim. Make sure the tire is inflated to the manufacturer’s recommended pressure.

Check the repair effect:

After reinstalling the tire, check for leaks. Use soapy water to check for bubbles around the patch.

Test Drive:

Perform a short test in a safe environment to ensure the repaired tire is functioning properly.

What are the signs that a radial tire needs to be patched?

Visible punctures or cuts:

Inspect the tread area for any visible punctures, cuts, or holes. Small punctures (usually less than 1/4 inch in diameter) may be repairable, while larger cuts or damage may require replacing the tire.

Air loss:

If you notice your tire pressure is dropping faster than usual, it could indicate a puncture or leak that needs attention. Check your tire pressure regularly to monitor for any noticeable drops.

Bumps or blisters:

Bumps or bubbles on the tire surface may indicate internal damage or weak spots in the tire. These areas may cause a blowout and should be checked by a professional.

Uneven wear:

Uneven tread wear could be a sign of a tire alignment problem or internal damage. If you notice heavy wear on one side of your tire, you may want to check to see if the tire needs repair.

Vibration or noise:

If you experience unusual vibrations or noises while driving, it could indicate a problem with your tires. This could be due to a blowout, internal damage, or another problem that needs attention.

Tire age and condition:

Even if there are no obvious signs of damage, old or heavily used tires may need to be inspected to determine if they need repair. Check the age of the tire (usually indicated by a DOT code) and consider replacing or repairing the tire if it shows signs of damage.

Check for foreign matter:

Check the tire for foreign objects, such as nails or screws, that may be embedded in the tread. If foreign objects are found, the tire may be able to be repaired if the puncture is small and located in the tread area.

Why is it unsafe to patch side wall damage on a tire?

Structural Integrity:

The tire sidewall is a critical structural component that supports the weight of the vehicle and absorbs impact forces. Damage to this area can compromise the integrity of the tire, leading to a higher risk of failure.

High Stress Area:

The sidewall is not subjected to the same pressures as the tread. It flexes more during driving, especially when turning. The patch may not be able to withstand these pressures, increasing the possibility of a blowout.

Limited repair options:

Sidewall damage usually consists of cuts, tears, or punctures that are too large or severe to be effectively repaired. Most tire manufacturers and safety guidelines recommend against repairing sidewall damage.

Possibility of air leakage:

Even with a patch, there is still a significant risk of air leakage over time. The dynamic nature of the sidewalls can cause the patch to fail, resulting in rapid air loss.

Safety Regulations:

Many tire manufacturers and safety organizations have strict guidelines that prohibit repairing sidewall damage. Ignoring these guidelines can result in unsafe driving conditions and may void any warranty on the tire.

Accident Risk:

Tire damage can lead to loss of control while driving, increasing the risk of an accident. This is particularly dangerous at high speeds or in bad weather conditions.