TIRE PATCH

Tire patches are an essential component in modern tire repair, offering a cost-effective solution to extend tire life and maintain road safety. In today’s automotive repair industry, quality tire patches play a crucial role in maintaining vehicle performance while reducing unnecessary tire replacement costs.

Sunsoul has emerged as a leading brand in this sector, providing reliable and durable tire repair solutions that meet the demands of both professional mechanics and wholesale dealers.

Why choose sunsoul tire patch

Advanced Material Technology

Sunsoul uses high-quality rubber compounds with specialized polymers for excellent heat and friction resistance, maintaining flexibility in extreme temperatures from -40°F to 250°F for reliable performance in all weather.

Leading Adhesion Properties

Sunsoul patches bonding strength, far exceeding industry standards. This exceptional adhesion prevents separation even under heavy loads and high-speed conditions.

Comprehensive Product Testing

– Pressure resistance testing up to 300 PSI

– Water immersion tests for 72 hours

– Peel strength measurements

– Long-term durability simulations

Environmental Compliance

Sunsoul patches meet all international environmental standards including RoHS and REACH certifications, containing no hazardous chemicals or heavy metals.

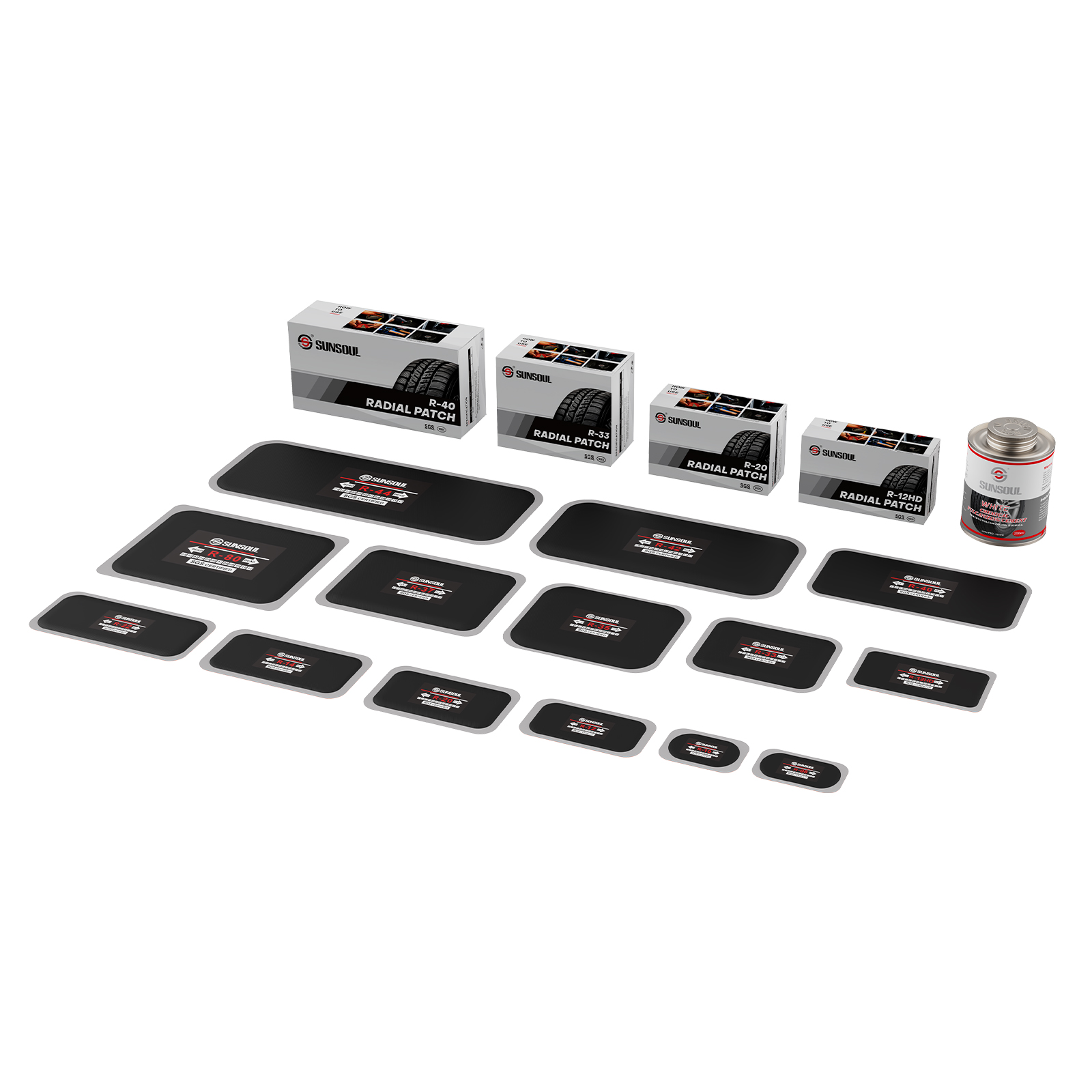

types of sunsoul rubber tire patch

SUNSOUL produces a variety of rubber tire patches, including vulcanizing tire patch, pre-buffed patches, tire patch plug kit, etc. With its first-class production line, SUNSOUL guarantees 2 million pieces of products per month.

Chemical Cure Tire Patch

– Self-vulcanizing compound activates upon contact with tire rubber

– Multi-layer construction with reinforced nylon center

– Bond strength: 98% of original tire material

– Available in sizes from 1″ to 3″ diameters

– Best for professional shop repairs, high-performance vehicle tires

Dual Cure Tire Patch

– Instant adhesive bond allows for faster return-to-service

– Progressive chemical curing continues for 72 hours

– Special textured surface enhances both bond types

– Medium-body rubber compound for optimal flexibility

– Best for fleet maintenance operations

tire patch plug kit

– High-tensile strength rubber plug stems

– Oversized repair patches for complete coverage

– Included insertion tools and reaming equipment

– Specialized rubber cement formulated for plug/patch combos

– Best for: Large punctures (up to 1/4″), angled injuries, and off-road tire damage

WHY Sunsoul

Robust business philosophy

Follow the business philosophy of “quality first, service first”. Its values are “serving customers first, creating value first”. Achieve sustainable profitable growth through a balanced business portfolio. Believe that excellent employees are the foundation of the company’s success.

Customer-centric service

Provide 24-hour pre-sales and after-sales service. Commit to rapid problem resolution within 72 hours, supported by a global service network. Customized support, including technical training, logistics optimization and 24/7 multi-lingual assistance, helps partners succeed.

Dealer support

They establish long-term win-win strategic partnerships with regional and national dealers, providing stable product supply, competitive pricing structure and regional cooperation support. Provide end-to-end solutions from R&D to after-sales support.

How to Choose the Right Tire Patch for Wholesale

Understand Tire Patch Types and Applications

Sunsoul offers a complete range of high-quality tire repair solutions:

– Rubber Patches: Premium vulcanized patches for inner tube repairs

– Self-Vulcanizing Patches: Advanced chemical-bonding technology requires no heat application

– Peel-and-Stick Patches: Convenient emergency solutions with improved adhesion formula

– Radial Patches: Heavy-duty construction specifically engineered for radial tire repairs

Evaluate Adhesive Compatibility

Sunsoul provides perfectly matched adhesive systems:

– Specially formulated rubber cement for traditional patches

– Pre-applied high-strength adhesive on peel-and-stick versions

– Chemical-activated bonding agents for self-vulcanizing patches

All adhesives are temperature-resistant (-40°C to +120°C) and waterproof

Assess Supplier Reputation

Sunsoul stands out with:

– 20+ years as a leading tire repair manufacturer

– Global distribution network serving 60+ countries

– Consistently high customer satisfaction ratings (98% positive feedback)

– Reliable bulk supply capacity with guaranteed delivery times

Check Product Quality and Certifications

Sunsoul products meet the highest industry standards:

– ISO 9001 certified manufacturing facilities

– DOT compliant for road safety

– CE marked for European markets

– Rigorous quality control with batch testing

– Environmentally friendly materials

tire patch for specific vehicles

Choosing the right rubber patch for tires is crucial for ensuring safety and longevity. The type of patch required depends on the vehicle’s weight, tire size, and driving conditions.

Passenger Cars & Sedans

Standard radial tires often use tire plug and patch kit for small punctures. These patches seal the inner liner and fill the injury channel.

SUVs & Light Trucks

Heavier loads demand reinforced patches or hot vulcanizing patches due to increased tire pressure and stress.

Commercial Trucks & Buses

Large punctures require heavy-duty tire patches with chemical bonding agents to withstand high mileage and weight.

Motorcycles & Performance Cars

Thin tires need low-profile patches (e.g., mushroom plugs) to avoid imbalance at high speeds.

Exceptions & Special Cases

Run-Flat Tires

Some manufacturers prohibit repairs; others allow only specific patches (e.g., Michelin’s ZP-rated tires).

Electric Vehicles

Heavier battery weight may require extra-strength patches to handle added stress.

Winter Tires

Cold conditions demand flexible, cold-resistant patches (e.g., butyl-based).

Off-Road & Agricultural Tires

Large injuries may need section repairs with specialized vulcanizing cement.

FAQ

SUNSOUL provides professional guidance. If you want to know more information, please contact us and we will respond in time!

Can Sunsoul patches be used on all tire types?

Yes, Sunsoul offers specialized formulations for:

– Radial tires (all speed ratings)

– Bias-ply tires (including trailer tires)

– Run-flat tires (using low-profile patches)

– Motorcycle tires (small diameter options)

– Agricultural tires (heavy-duty versions)

How should I apply Sunsoul tire patches for best results?

1. Prepare the Damaged Area

– Locate the puncture and mark its position

– Clean the area thoroughly with the included cleaning solution

– Use the provided rasp tool to roughen the surface around the puncture

– Remove all debris and dust from the repair area

2. Select the Correct Patch Type

– Choose the appropriate Sunsoul patch size (should extend at least 1/2 inch beyond puncture)

– For tube tires: use Sunsoul rubber or self-vulcanizing patches

– For tubeless tires: use Sunsoul radial or heavy-duty patches

3. Apply Adhesive (if required)

– For traditional patches: apply Sunsoul special cement evenly

– Wait 2-3 minutes until cement becomes tacky

– For self-vulcanizing patches: no adhesive needed

4. Install the Patch

– Remove protective backing from patch

– Center patch directly over puncture

– Apply firm pressure for 30-60 seconds

– Use roller tool to ensure complete adhesion (included in repair kits)

5. Final Inspection

– Check edges are completely sealed

– Ensure no air bubbles under patch

– Wipe away excess cement

– Allow proper curing time (15 minutes minimum)

For technical support or application questions, contact Sunsoul customer service.

How much to patch a tire?

The cost of a flat tire repair can vary widely based on a number of factors, including the type of tire, the extent of the damage, and where the repair is being done. On average, a flat tire repair usually costs between $10 and $30.

Tire Type: Passenger car tires are generally less expensive to repair than larger tires used on SUVs or trucks, which may require more extensive repairs.

Extent of Damage: Minor punctures can be repaired at a low cost, while larger damage or sidewall issues may require more complex repairs or even replacements, increasing the overall cost.

Repair Location: If repaired at a tire shop, labor costs may be included in the price. Door-to-door tire repair services may incur additional charges for the convenience of the customer.

How Long Does It Take to Patch a Tire?

Repairing a tire usually takes about 30 minutes to an hour, depending on several factors, including:

Technician’s experience: A skilled technician can complete the job faster than an inexperienced technician.

Tire Type: Certain tires, such as those with complex designs or run-flat tires, may take longer to repair.

Where: If you have your tire repaired at a shop, it will probably take less time than if you do it yourself at home.

Tire Condition: If a tire has multiple punctures or other damage, it may take more time to evaluate and repair.

Tools and Equipment: Having the right tools ready can speed up the process.

How Close to Sidewall Can a Tire Be Patched?

1. General Rule:

– Repairable area: Must be within the central 3/4 of tread (measured from shoulder to shoulder)

– Absolute minimum: 1/2 inch (12mm) from sidewall edge

– No repairs permitted in actual sidewall/flex zone

2. Repair Limitations:

– Punctures at tread/sidewall junction cannot be safely patched

– Angle matters: Punctures >25 degrees often disqualify even if within repairable zone

– Size restriction: Holes >1/4 inch (6mm) near sidewall are unsafe to repair

Safety Note: Any repair near sidewall compromises tire integrity. When in doubt, replacement is the only safe option. The closer to sidewall, the higher the risk of patch failure and blowout.