truck tire patch

A truck tire patch is a tool or material used to repair damage to a tire, usually to close small holes or cracks in the tire to prevent air from leaking out. The patch can be a rubber material, usually used with an adhesive, that is applied to the tread portion of the tire.

Economic

Using a patch repair can save costs compared to replacing the entire tire.

Environmentally friendly

Repairing your tires helps reduce waste and extend the life of your tires.

truck tire repair patches types

the location and size of the damage, and whether the tire is tubeless or has an inner tube.

Plug Patches

A hybrid repair combining a rubber tire patch (applied internally) and rubber tire plugs (inserted into the puncture).

Use Case:

Ideal for radial truck tires with punctures in the tread area (crown).

Repairs both the inner liner and the injury channel.

Vulcanizing (Hot Cure) Patches

Requires a chemical vulcanizing process to bond the patch to the tire’s inner liner using heat and pressure.

Use Case:

Repairs larger injuries (e.g., cuts, gashes) in bias-ply truck tires or older radial tires.

Cold Patches (Self-Vulcanizing)

Pre-coated patches that bond chemically without external heat. Applied with cement and pressure.

Use Case:

Quick repairs for small punctures (≤6 mm) in the tread area.

It is a special material used to repair punctures or tears on the inner tubes of pneumatic tires, which are commonly found on old-fashioned or truck tires with inner tubes.

Use Case:

For truck tires with inner tubes (common in older or specialty vehicles).

Bead Repair Kits

Specialized patches or sealants to repair damage near the tire bead (where the tire seals to the rim).

Use Case:

Minor bead area leaks or corrosion.

Tire Sealants

Liquid or foam injected into the tire to seal small punctures temporarily.

Use Case:

Emergency roadside fixes.

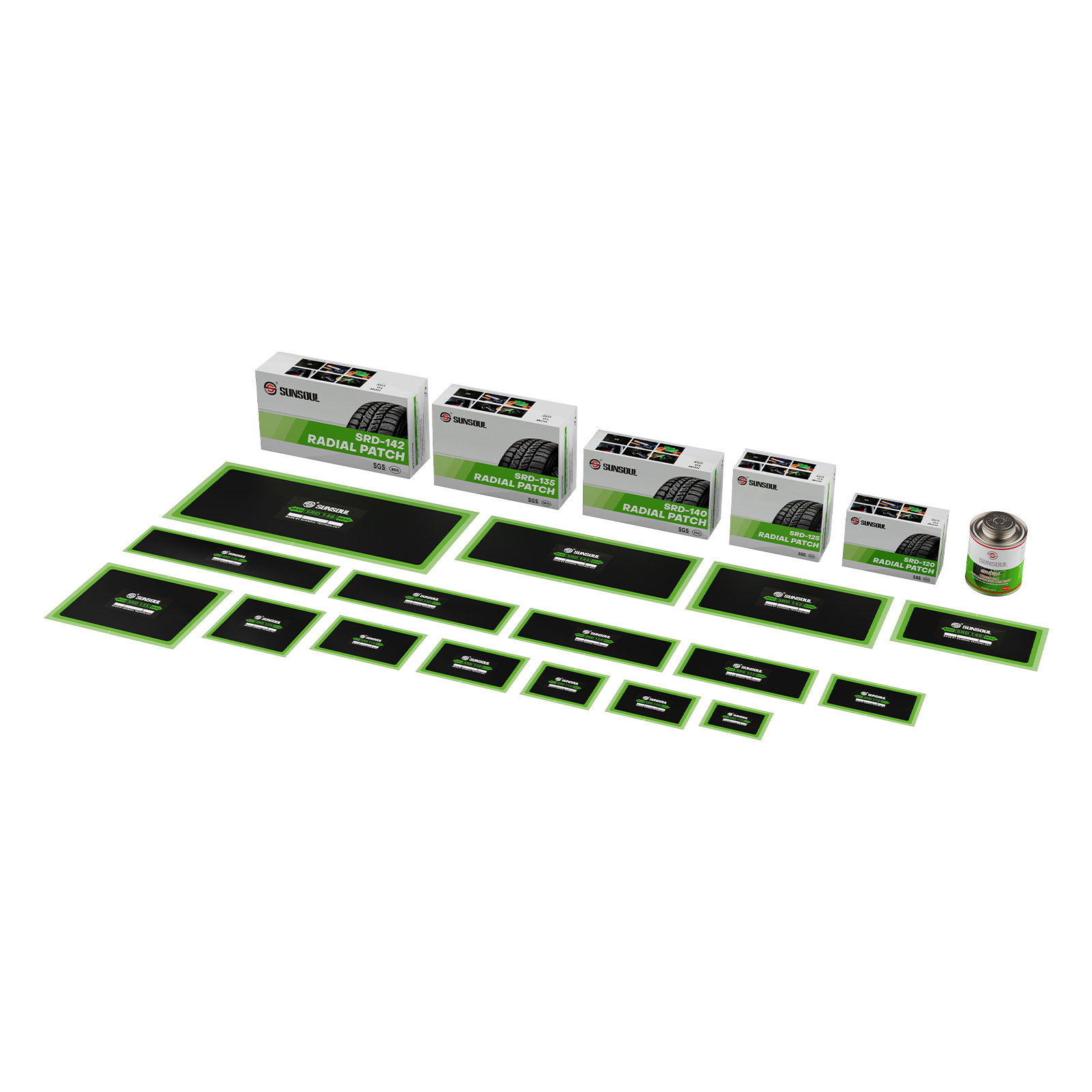

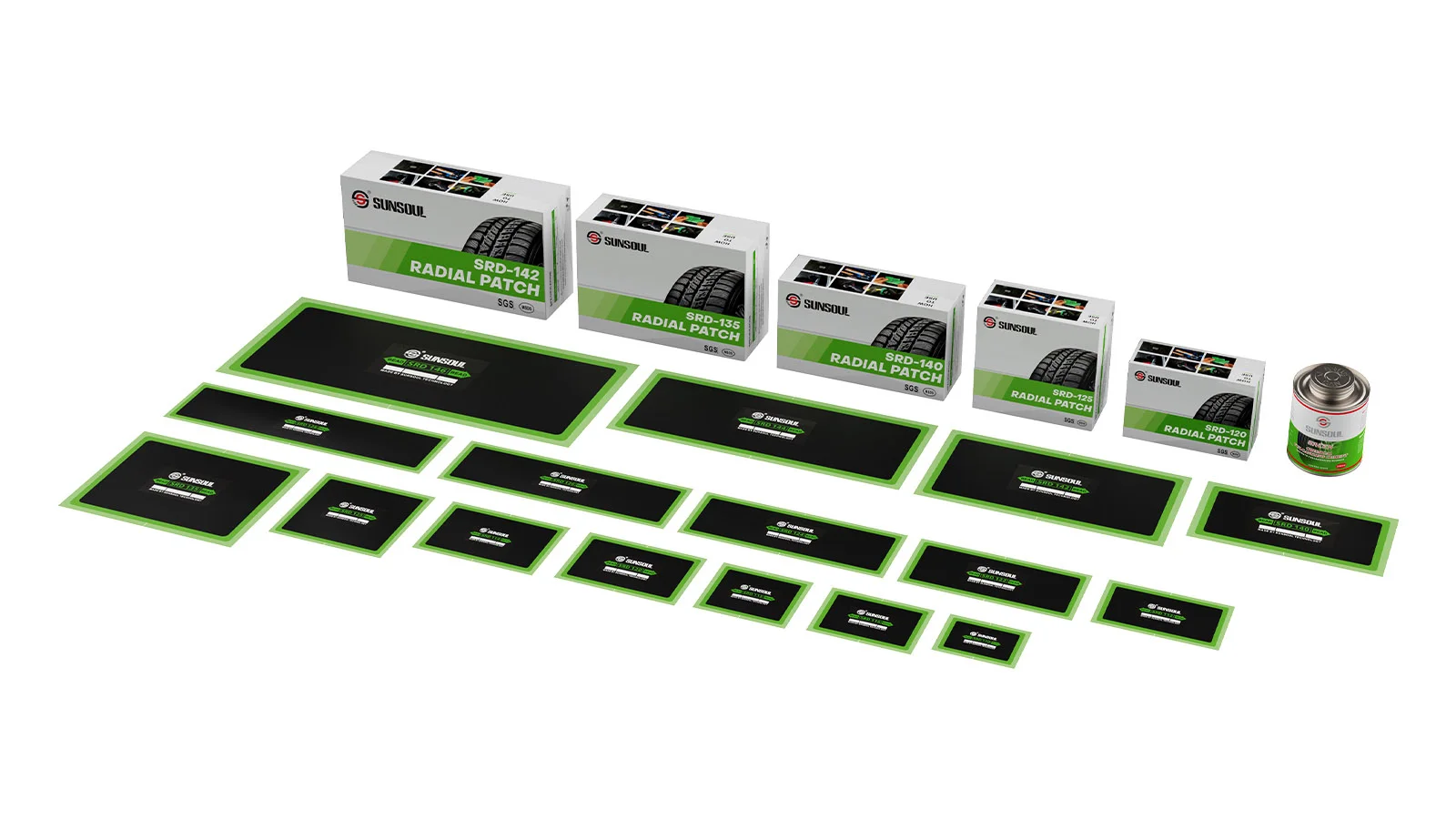

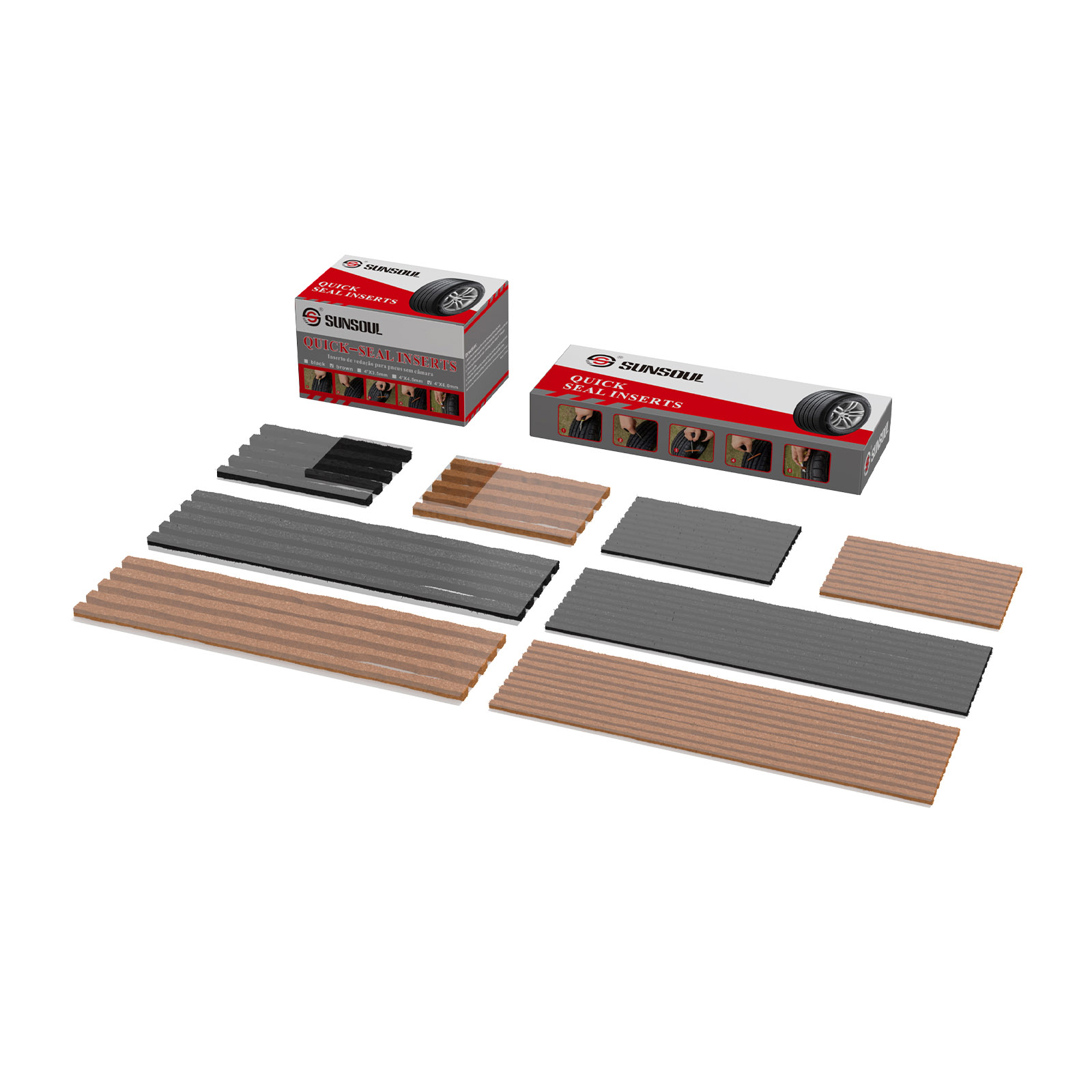

sunsooul commercial truck tire patches

heavy truck tire patches application

As a professional truck tire patch manufacturer, sunsoul provides a variety of solutions for heavy truck tire repair.

Applicable objects:

Designed for heavy-duty working vehicles such as engineering vehicles, mining trucks, and dump trucks, it can cope with high loads (single tire bearing 4-8 tons), complex road conditions (gravel, steel bars, mud) and extreme temperatures (-40°C to 120°C).

Key differences between heavy duty truck tire patch kit and ordinary truck tire patch kit:

1. Material performance: Heavy-duty tool kits use composite reinforced materials, and their tensile/tear resistance is 2-3 times that of ordinary tools.

2. Process requirements: It must be combined with a heated vulcanization process, while ordinary tools only require physical filling or cold bonding.

3. Safety redundancy: Heavy-duty repairs must pass X-ray flaw detection and load testing, while ordinary repairs only rely on visual inspection.

4. Economical: Heavy-duty tool kits have a high cost per time, but avoid replacing engineering tires of $2000+; ordinary tools are suitable for low-cost and quick repairs.

Step-by-Step Guide to Applying heavy truck tire patches

Hole and Crack Repair: Heavy truck tires may develop small holes or cracks during use, and truck tire patches can effectively seal these damages and prevent air leaks.

Inner tube repair: In some cases, heavy truck tires use inner tubes, and heavy truck tire patches can be used to repair inner tube leaks.

Multi-layer repair: For larger or more severe damage, multiple layers of patches may be required for reinforcement to ensure the structural integrity of the tire.

High temperature and high pressure environment: Heavy truck tires are used in high temperature and high pressure working environments, so the truck tyre repair patches need to have high temperature and pressure resistance to ensure the repair effect is long-lasting.

Emergency repair: When encountering tire damage on the road, heavy truck tire patches can be used as an emergency repair solution to help drivers quickly restore driving ability.

truck tyre repair patches brands

SUNSOUL

SUNSOUL is an experienced, quality- and service-oriented Chinese manufacturer that offers a wide range of automotive repair parts, including tire patches, and is actively expanding into international markets.

TECH

TECH is known for its innovation in cold vulcanization technology, has a comprehensive product line, is recognized by global tire manufacturers for its quality, and has a complete customer support network.

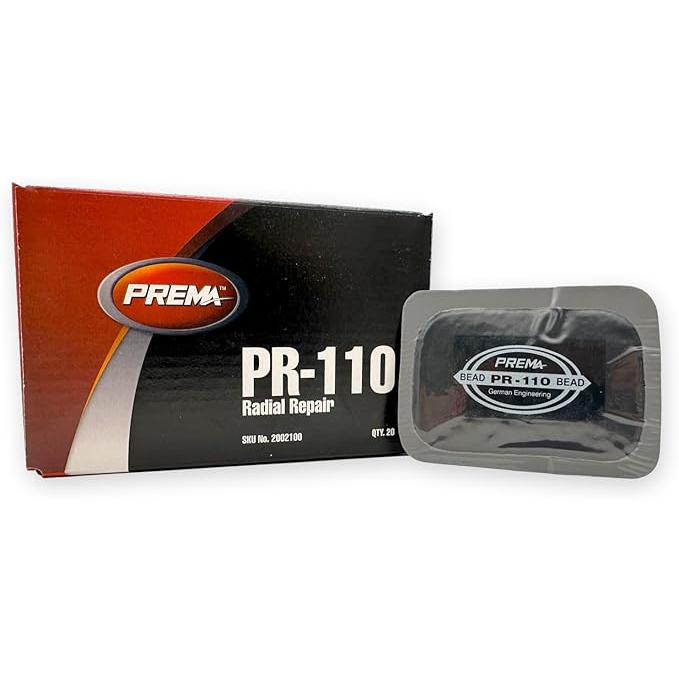

PREMA

PREMA focuses on high-quality soft rubber tire repair solutions, with a professional and rigorously tested product line and provides users with rich technical resources.

REMA

REMA TIP TOP is a long-established global company that not only provides high-quality products in the field of tire repair, but also provides a wide range of solutions in the industrial field.

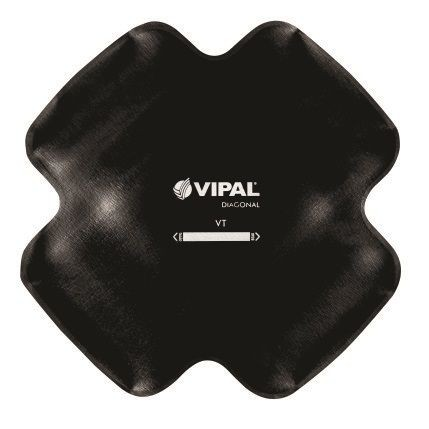

Vipal Rubber

As a leading global rubber manufacturer, Vipal Rubber has strong strength and comprehensive solutions in both tire retreading and repair.

SUNSOUL Professional answers

Can’t find the answer you need in the options below? Our Customer Service Team is happy to help! Contact us here.

about truck tire patch

How much damage can a truck tire patch repair?

Repairable conditions

Puncture diameter

Maximum allowable size: ≤ 1/4 inch (about 6 mm)

Exceeding this size may cause the inner cord layer to break, and the repair is prone to failure.

Damage location

Central area of tread only

Damage type

Straight puncture (such as round holes caused by nails and screws)

No internal cord breakage or delamination

No carcass (inner cord layer) damage

How long is the lifespan of a truck tire patch?

Factors Affecting Lifespan

Quality of Repair

A certified patch-plug repair (applied from the inside after demounting the tire) can last 50,000–100,000+ miles or 2–5 years, depending on tire usage.

Poorly executed repairs (e.g., skipping vulcanization, improper cleaning) may fail within weeks or months.

Load and Driving Conditions

Overloading, high speeds, or frequent off-road use generate heat and stress, accelerating patch failure.

Patches on tires used for heavy haulage may wear faster than those on lightly loaded vehicles.

Environmental Factors

Exposure to extreme temperatures, road chemicals, or moisture can degrade the adhesive bond over time.

How does one fix a truck tire patch that has failed in a tire?

If a truck tire patch fails, it is generally unsafe to re-repair the same damaged area, as the tire’s structural integrity may be compromised. Truck tires endure heavy loads and high stress, so a failed patch often signals that the tire is no longer roadworthy.

1. Do Not Attempt a Second Repair

– Industry standards (e.g., Rubber Manufacturers Association) state that a failed repair voids the tire’s eligibility for re-repair.

– A second patch on the same spot will not restore reliability and risks catastrophic failure (e.g., blowouts, tread separation).

2. Replace the Tire

Immediately replace the tire with a new or properly retreaded one.

about sunsoul

What is your minimum order quantity?

For wholesale sales, the MOQ is always one package; however, you can purchase a sample for a trial order.

Which payment options are available for full-order purchases?

A number of payment options are accessible, including as T/T, Western Union, Visa, MasterCard, Alibaba Trade Assurance, and PayPal.

Can you ship straight to an FBA fulfillment center, door to door?

We offer UPC code and Amazon FBA warehouse delivery services. Printing and labeling are free. HD pictures for free.

After an order is placed, how long does it take to manufacture?

Generally speaking, it will take 30 to 40 days after receiving your deposit for non-online products.

Do you test all your goods before delivery?

Yes, we have quality control all through our production and have final inspection by QC with AQL standard before shipment.