tubeless tire patch

A tubeless tire patch is a durable, adhesive-backed repair solution, commonly used in bicycles, motorcycles, and even some automotive applications. Unlike traditional inner tube patches, tubeless tyre patch creates an airtight seal from the inside, preventing air loss and ensuring long-lasting performance.

Whether you’re a cycling, a tire repair shop, or a patch tubeless dealer, choose SUNSOUL tubeless tire patch—can save you time, money, and hassle.

Strong & Flexible Bond – High-quality rubber patches vulcanize with the tire for a permanent repair.

Prevents slow leaks, maintaining optimal tire pressure.

Cost-Effective Solution – Extends tire life instead of requiring a full replacement.

Quick & Easy Application – Many kits include all necessary tools for on-the-go repairs.

tubeless tire repair tools in tyre patch kit

A tubeless tire repair kit is a must-have for cyclists, motorcyclists, and off-road drivers who want to quickly fix punctures without replacing the entire tire.

Vulcanizing Glue

Activates the chemical bonding process for a secure seal.

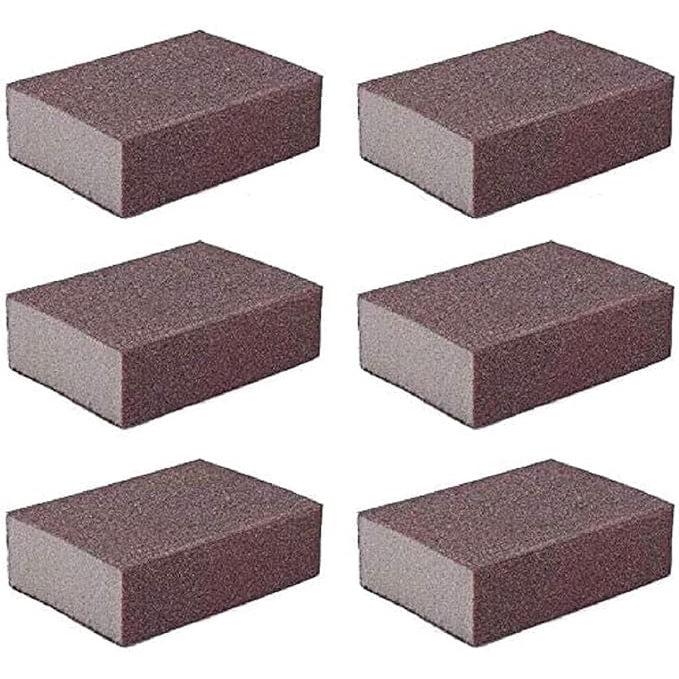

Sandpaper or Buffing Tool

Roughens the tire surface for better adhesion.

Tire Reamer/Plug Insertion Tool

Cleans the puncture hole and helps insert plugs (if included).

Valve Core Remover

Allows easy access when applying sealant or patches.

How to Choose the Right tubeless tire puncture kit for Tire Type

Different tires face unique stresses—MTBs endure rocks and roots, road bikes need speed-worthy seals, and motorcycle tires require heavy-duty tubeless tire puncture kit solutions.

Key Requirements:

✔ Larger Patches (1.5–2″) – MTB tires endure rocks, thorns, and aggressive flexing.

✔ Flexible Rubber – Must stretch with knobby tires without peeling.

✔ Sealant-Compatible – Many MTB riders use sealant + patches for best results.

✔ Durable Plug/Patch Combos – For larger trailside punctures.

Road bicycle tubeless tire repair kit

Key Requirements:

✔ Small, Thin Patches (0.75–1″) – Avoids imbalance at high speeds (80–100+ PSI).

✔ Precision Adhesive – Smooth road tires need flawless seals.

✔ Lightweight & Compact – Fits in a saddle bag.

✔ Fiber-Reinforced Patches – For high-pressure stability.

Key Requirements:

✔ Heavy-Duty Patches (2–3″) – Must handle heat, weight, and highway speeds.

✔ Industrial-Grade Glue – Standard bike glue fails under motorcycle stress.

✔ Plug + Patch Combos – Best for larger punctures.

✔ DOT-Approved Kits – Ensures safety for street riding.

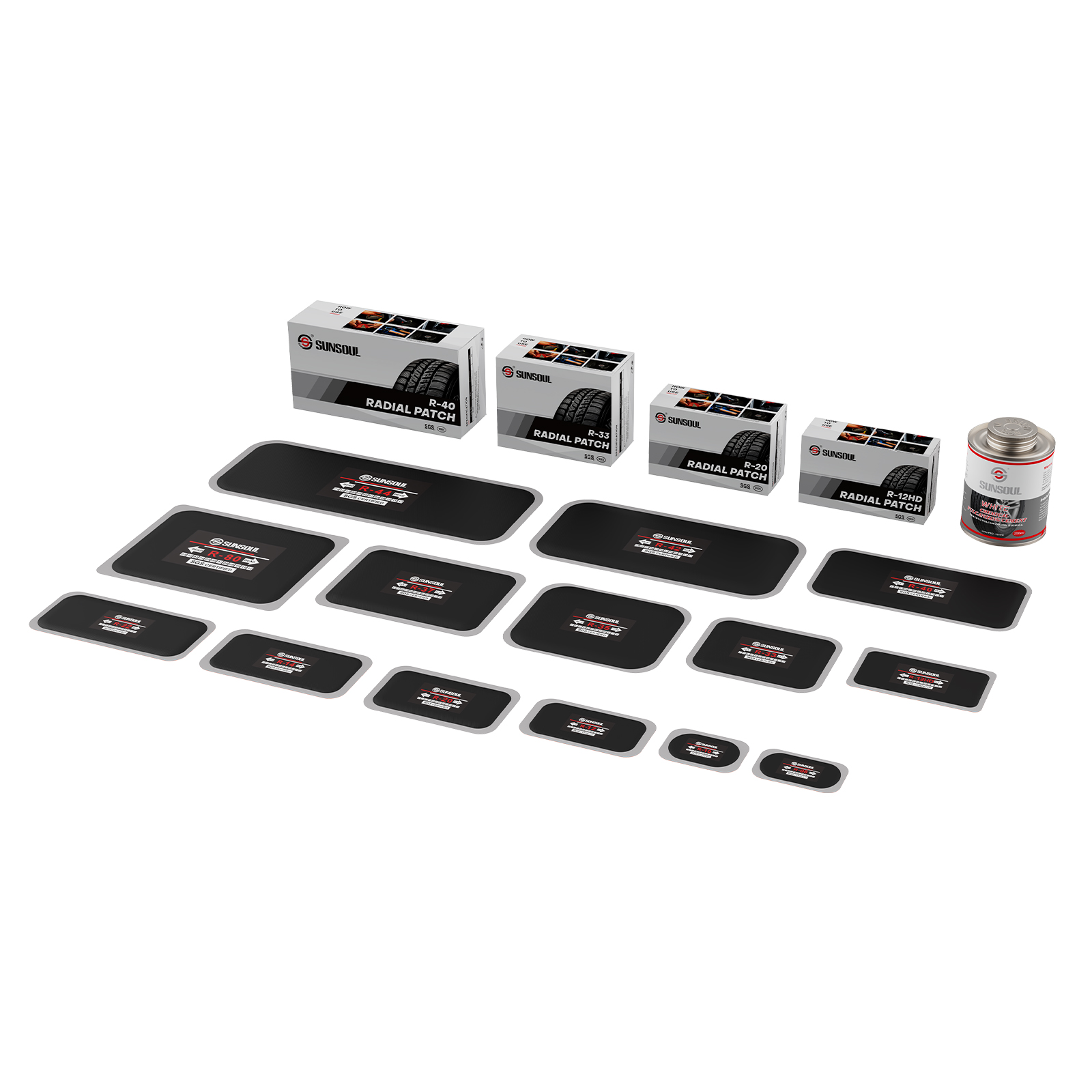

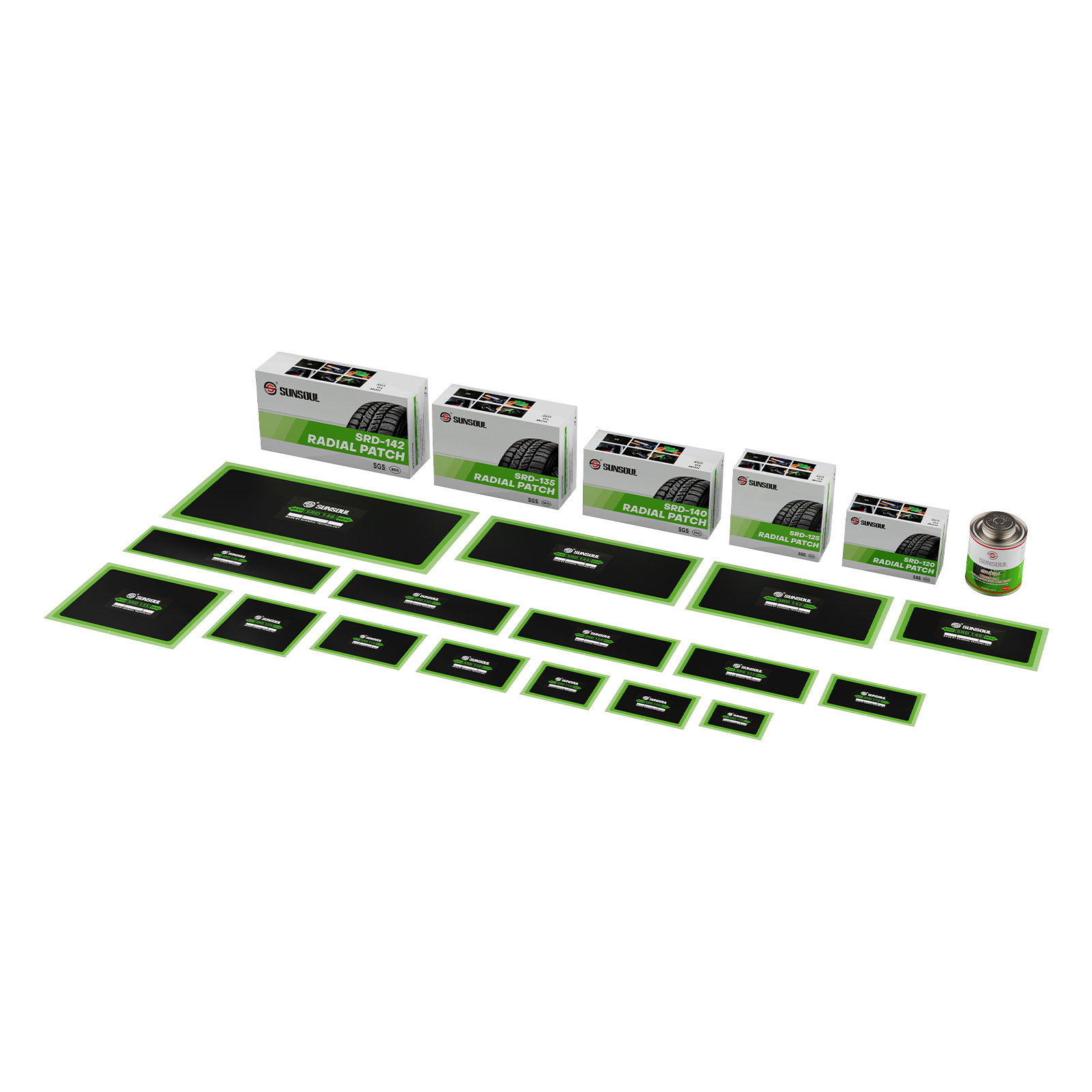

SUNSOUL tire patch tubeless

why choose SUNSOUL

Extensive industry expertise: With over two decades of market presence, SUNSOUL delivers proven solutions to help clients grow their business and boost revenue.

High-volume manufacturing: Our facilities have a monthly output exceeding 2 million tire patches, serving diverse sectors including bicycle, motorcycle, automotive and agricultural equipment markets.

Brand enhancement strategy: We strengthen brand visibility through customized marketing campaigns, strategic partnerships, and active participation in international exhibitions including Automechanika and SEMA.

Environmental commitment: Utilizing sustainable materials and energy-efficient manufacturing processes aligns with worldwide environmental objectives and minimizes ecological impact.

Progressive research and development: Our skilled engineering team consistently enhances product designs to comply with evolving industry requirements and environmental policies.

Dedicated customer support: Offering round-the-clock pre-sales and post-sales assistance with guaranteed 72-hour response time for issue resolution, backed by our worldwide service infrastructure.

Provide regional cooperation support and training center resources to ensure stable product supply and competitive pricing structure.

Provide end-to-end solutions, integrating operations from R&D to after-sales support, ensuring seamless quality control and rapid market response.

Provide unparalleled after-sales service, promising prompt problem resolution within 72 hours, and backed by a global service center network.

Provide tailored support, including technical training, logistics optimization and multi-language assistance to help partners maximize product value.

welcome to become SUNSOUL dealer

sunsoul provides expert guidance on tubeless tire maintenance

Tubeless Tire Care & Repair Basics

Keep Tire Pressure in Check Regularly (Before Every Ride / Weekly)

Always start with the right tire pressure. Use a reliable gauge before each ride or at least once a week. Proper inflation helps prevent air leaks and improves the performance of your tire tubeless repair kit when fixing any issues on the trail.

Maintain Sealant Levels for Reliable Protection (Monthly)

Tubeless sealant slowly dries over time. Check your tires once a month and top off the sealant if needed. The right amount of sealant ensures your tire can self-seal small holes — reducing the need for a tubeless tyre patch or other roadside repairs.

Examine Tires and Rim Tape for Hidden Damage (Every 3 Months)

Every few months, carefully inspect your tires for cuts, cracks, or sidewall wear. Also, check that the rim tape is smooth and airtight. A well-sealed rim helps your tubeless repair patch or sealant work effectively when repairing punctures.

Give Your Tubeless Setup a Seasonal Refresh (Every Season)

Seasonally, remove your tires and give the rims a deep clean. Replace old sealant and check the rim bed for dirt or corrosion. This refresh ensures that your tubeless tyre patch and sealant will stick and seal properly when needed.

Keep Valve Cores Clean and Flowing Freely (Every 3 Months)

Valve cores can clog with dried sealant. Unscrew, clean, or replace them regularly to keep air flowing smoothly. A clean valve helps you inflate your tires faster — especially when using tools from your tire tubeless repair kit.

Be Ready to Plug Punctures Anytime

Always carry a tire tubeless repair kit for emergencies. If a puncture is too large for the sealant to fix, insert a tubeless repair patch or tubeless tyre patch directly into the hole to seal it instantly and keep riding with confidence.

Tubeless Tire Repair Troubleshooting

Slow Air Leaks or Pressure Loss

If your tire slowly loses air, first check the valve core — it may be loose or clogged. Tighten it gently or replace it if necessary. If the problem continues, inspect the rim tape and bead for gaps or dried sealant. Reseal the rim and add fresh sealant to restore an airtight fit.

Sealant Not Sealing Punctures

When a puncture doesn’t seal right away, spin and shake the wheel to spread the sealant. If air keeps escaping, the hole might be too large for the sealant alone. Insert a tubeless repair patch or tubeless tyre patch directly into the puncture using your tire tubeless repair kit.

Burping or Sudden Air Loss

A loud “burp” sound usually means the tire bead temporarily unseated from the rim. Check your tire pressure — it may be too low. Clean the bead and rim edges, re-seat the tire, and inflate to the correct pressure. Adding a bit more sealant can also help prevent future burping.

Clogged Valve or Difficult Inflation

If it’s hard to pump air into the tire, remove and clean the valve core. Dried sealant often blocks airflow. Rinse the core with warm water or replace it entirely. Keeping spare cores in your tire tubeless repair kit saves time on the trail.

Sealant Drying Out Too Quickly

If you notice your sealant drying within weeks, your tire or rim tape might be leaking air. Check for small cuts or weak spots in the tape. Reapply new rim tape and refill with fresh sealant to keep your tubeless system airtight and effective.

Puncture Won’t Hold a Plug

When a plug pops out or fails to seal, clean the hole and insert a slightly larger tubeless tyre patch or tubeless repair patch. Make sure the area is dry before applying pressure to set the patch securely. If the damage is too big, it may be time to replace the tire.

how do tubeless repair patch work

Tubeless repair patch is vulcanized to create a permanent, airtight seal. This molecular-level fusion creates a patch that is typically stronger than the surrounding tire material and can withstand flexing, heat, and pressure changes. Fully bonded to the tread in just 24 hours.

The Repair Process

Locate & Prepare the Puncture – Clean the area and roughen it with sandpaper for better adhesion.

Apply Vulcanizing Glue – Activates the rubber’s bonding agents.

Place the Patch – Press firmly to ensure full contact and remove air bubbles.

Cure Under Pressure – The glue chemically bonds the patch to the tire, creating a seamless repair.

Temporary vs. Permanent Repair Methods

Temporary Solutions

Tire Plugs: Quick trailside fixes that fill holes but don’t bond chemically

Sealant Alone: Works for pinholes but fails on larger punctures

Pros: Fast application, no tire removal needed

Cons: Short lifespan (days to weeks), not pressure-stable

Permanent Patches

Vulcanizing tire patch: Create molecular bonds with the tire

Pros: Lasts the tire’s remaining life, maintains air pressure perfectly

Cons: Requires tire removal, longer installation time

Role of Sealant in Conjunction with tubeless repair patch

Initial Sealing: Sealant stops air loss during patch preparation

Puncture Cleaning: Sealant keeps hole debris-free for better adhesion

Backup Protection: Provides secondary sealing if patch edges lift

Future-Proofing: Guards against new small punctures

Which Patch is Recommended for Tubeless Tire Puncture Repair?

Choose the right tubeless patch to ensure a safe and lasting repair. Tubeless tire patch expert SUNSOUL gives you professional advice

Best tubeless tire Patch for Different Scenarios

Top 3 tubeless tyre patch expert recommendations

SUNSOUL Professional Series

Military-grade vulcanizing compound

Pre-buffered patches require less preparation

Temperature-resistant (-40°F to 250°F)

Rema Tip Top

Pros: German-engineered precision

Cons: Higher cost, limited sizes

Park Tool

Pros: Excellent for bicycle shops

Cons: Smaller patch selection

tubeless tire patch common faq

Is tubeless tire patch permanent?

Can I patch a tubeless tire more than once?

How long does a patched tubeless tire last?

Can I use a tube-type patch on a tubeless tire?

No – Tube patches lack the thickness and adhesive strength needed for tubeless tires. Always use tubeless-specific patches (like SUNSOUL’s butyl rubber kits).

How do I store unused tubeless tire patch?

Keep in cool, dry place (avoid gloveboxes!)

Seal glue tightly to prevent drying

Replace if patches become brittle (>2 years old)

What PSI Can tubeless tire patch Handle?

High-quality vulcanizing patches can withstand:

Road bikes: 100+ PSI when fully cured.

MTB/Motorcycle: 30-50 PSI reliably.

Pro Tip: After repair, initially inflate 10-15 PSI below max to test seal integrity. Avoid sudden pressure spikes during first 48 hours.

Can You Patch Tires in Cold Weather?

Yes, with adjustments:

Use winter-grade vulcanizing glue (cures at low temps).

Pre-warm tire interior with a heat gun (<50°C).

Extend curing time by 50%.

Warning: Never apply patches to frost-covered surfaces.

How to Check If a tubeless tire patch Is Fully Vulcanized?

Nail test: Gently scratch patch edges – no lifting if bonded.

Flex test: Bend tire – no cracking sounds at repair site.

Soap test: Apply soapy water – zero bubbles = perfect seal.

Full cure typically takes 24 hours for maximum strength.

How to Safely Remove Old tubeless tire patch?

Heat patch to 60-70°C with a heat gun (softens adhesive).

Peel slowly using plastic tire levers (metal tools damage casing).

Remove residue with citrus-based cleaner (not acetone).