Vulcanizing Tire Patch

Vulcanizing tire patches is a process that involves chemically bonding rubber materials together to create a strong and durable repair.

If you have a tire with an inner tube or prefer a traditional repair method, a hot vulcanizing patch could be suitable. However, for tubeless tires or when a more secure seal is required, cold patches are typically recommended. No matter what, you can find the perfect tire repair solution at SUNSOUL.

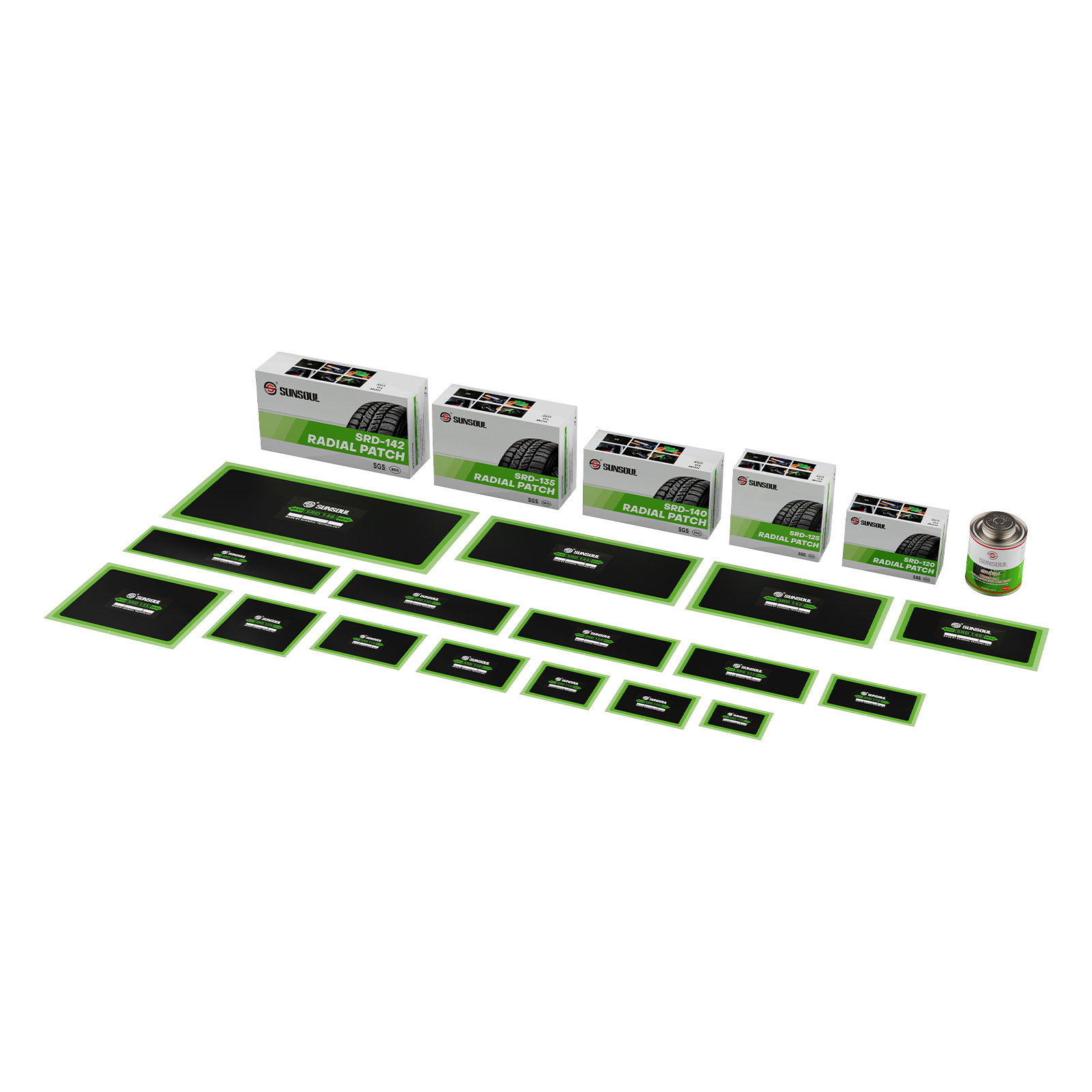

Founded in 2013, SUNSOUL has established ourselves as a leader in the production of vulcanizing rubber patch, serving over 300 customers worldwide and exporting to more than 60 countries. With a focus on quality and innovation, SUNSOUL offers a wide range of vulcanizing tire patches designed to cater to various vehicle types and tire needs. Our vulcanize kits are suitable for cars, vans, trucks, off-the-road (OTR) vehicles, bicycles, and motorcycles.

Features of vulcanizing tire patch

Durability and Strength

Vulcanized patches create a strong chemical bond. This process involves adding cross-links to the rubber molecules, which increases the strength and durability of the repair.

Long-Term Performance

Vulcanized patches are more reliable for long-term use compared to adhesive patches, which may fail over time due to the adhesive weakening or the patch peeling off.

Chemical Bonding

Unlike adhesive patches that rely on glue, vulcanized patches form a chemical bond with the rubber, making the repair more permanent and resistant to stress and pressure.

Best Vulcanizing Tire Patch Kit from SUNSOUL

Why choose SUNSOUL's

vulcanized patch kit

SUNSOUL’s vulcanized patch kit offers a reliable and cost-effective solution for repairing punctures, making it a good choice for those seeking a durable and long-lasting fix.

Material Quality

SUNSOUL patches are made from high-quality materials, including natural rubber, which provides excellent durability and flexibility. The use of a black vulcanized layer ensures superior adhesion, enhancing the patch's longevity.

Design and Structure

The patches feature a textile reinforcement, which contributes to their unparalleled durability. This design ensures that the patches can withstand various conditions and maintain their integrity over time.

Vulcanization Process

Vulcanizing patches literally fuse the patch to the tire or tube, creating a permanent bond. This process, when done correctly, results in a repair that is as strong as the original material.

Warranty and Quality Control

SUNSOUL offers an 18-month warranty for their products, indicating confidence in their durability. Additionally, they have a rigorous quality control process, ensuring that all products meet international standards.

Type of vulcanizing tire patch

Vulcanizing tire patches are used to repair tire punctures by creating a strong bond between the patch and the tire. There are two main types of vulcanizing patches: hot vulcanizing and cold vulcanizing. Each has its own application scenarios based on the type of damage and the location on the tire.

Hot vulcanizing patches

Hot vulcanizing involves applying heat and pressure to bond the patch with the tire. This process creates strong chemical bonds, making it ideal for heavy-duty repairs, especially for large cuts or significant damage on the tread or sidewalls. Hot vulcanization ensures a durable repair that maintains the tire’s flexibility and performance.

Common Usage Scenarios:

Large Cuts

Ideal for repairing large cuts on the tread or sidewalls where structural integrity needs to be maintained.

Sidewall Repairs

Effective for repairing cracks or small hernias on the sidewalls.

Heavy-Duty Tires

Often used for agricultural or construction tires that require robust repairs.

Cold patch vulcanizing

Cold vulcanizing patch uses chemical adhesives to form a strong bond between the patch and the tire without heat. It is more suitable for DIY repairs and is typically used for punctures rather than cuts. Cold vulcanization is best applied to the tread area where the structure is more solid and less prone to flexion.

Common Usage Scenarios:

Tread Punctures

Suitable for repairing small punctures on the tread area.

DIY Repairs

Convenient for home repairs when specialized equipment for hot vulcanization is not available.

Less Severe Damage

Ideal for minor punctures where the internal structure of the tire remains intact.

When to use a vulcanized patch kit

Not all tire punctures are the same. Some are small, but others are huge. Some punctures may penetrate the sidewall, and some will bury themselves within the tread surface. Your tire can be safely vulcanized if the following conditions hold true.

Size of the Puncture

A puncture in your tire should be no larger than one-quarter inch (1/4") in diameter. Larger punctures may require a different repair method or even require replacing the tire.

Location of the Puncture

The puncture must be located within the tire's surface patch, crown area. Sidewall punctures typically cannot be repaired with patches and may require replacement.

Distance from Other Repairs

The puncture should not overlap with previous repair patches. If there are multiple punctures, they should be at least 16 inches apart to ensure safe vulcanization.

Type of Damage

Vulcanizing is suitable for repairing cracks and punctures but is not recommended for extensive damage that compromises the tire's structural integrity.

Your Trusted Partner in Vulcanizing Tire Repair Solutions

As a leading manufacturer of vulcanizing tire patches, SUNSOUL is committed to expanding its global network of dealers. With a strong focus on innovation, quality, and customer satisfaction, we offer a comprehensive range of tire repair materials designed to meet the evolving needs of the automotive industry.

Global Reach and Recognition

- Market Penetration: Our products are strategically distributed across South America, Europe, North America, Australia, and Southeast Asia, reaching over 60 countries and establishing us as a reliable brand worldwide.

- International Certifications: Our manufacturing processes are ISO-certified, ensuring compliance with international safety and performance standards.

Customer-Centric Support

- Tailored Assistance: We provide technical training, logistics optimization, and 24/7 multilingual support to empower our partners and ensure their success.

- Brand Empowerment: Through targeted marketing campaigns and participation in major trade exhibitions like Automechanika and SEMA, we enhance brand visibility and support our partners' growth.

Sustainability and Responsibility

- Eco-Friendly Practices: We prioritize the use of eco-friendly materials and energy-efficient production methods, aligning with global sustainability goals and reducing our operational footprint.

- Community Engagement: Our commitment to ethical business practices and community engagement fosters a culture of accountability and excellence.

Comprehensive Service Solutions

Q&A about Vulcanizing Patches

The drying time for vulcanizing patches, specifically the vulcanizing fluid used to adhere them, can vary depending on the product and environmental conditions.

For most vulcanizing fluids, it takes a few minutes to about 10 minutes for the surface to become non-shiny, indicating it is ready for the patch to be applied. Cold or humid conditions can significantly increase drying times. In such cases, it may be necessary to double the recommended drying time.

Waiting until the surface is no longer shiny is a good indicator that it is ready for patch application. Or touch the area lightly with your finger. If the fluid feels tacky but does not stick to your finger, it is ready.

The main difference between vulcanizing patches and tire plugs lies in their application, durability, and repair type.

Application: Vulcanizing patches require removing the tire from the rim to apply a patch to the inner tube or tire casing using heat, creating a strong chemical seal. In contrast, tire plugs are inserted from the outside without removing the tire, relying on internal pressure for a compression seal.

Durability: Vulcanizing patches are more durable and long-lasting, suitable for larger punctures and lasting as long as the tire. Tire plugs are less durable and recommended for temporary repairs of smaller punctures.

Repair Type: Vulcanizing patches provide a more permanent fix, while tire plugs are quicker but less secure, ideal for emergency situations.

Here are some highly recommended brands for vulcanizing patches, including:

REMA: Offers vulcanizing patches made from high-quality materials, designed for durability and ease of use. These patches are suitable for various tire types, including passenger and off-road tires.

VERMAR: They offers a variety of tire repair patches, including radial tire repair patches like the XR-14 model, which is designed for tread, shoulder, and sidewall repairs.

SUNSOUL: Known for their high-quality vulcanizing patches, SUNSOUL offers a variety of sizes suitable for different types of tubes. Our patches are designed to stretch evenly, providing a seamless repair when used with cold vulcanizing fluid.

PREMA: Specializes in radial tire repair patches, which can be installed using either cold or hot vulcanization methods. Their patches are designed for repairs in the crown, shoulder, and sidewall areas of tires.

Identify the Puncture: Locate the hole or puncture in the tire. If needed, inflate the tire slightly to make the hole more visible.

Prepare the Surface: Use sandpaper or a metal file to scuff the area around the puncture. Clean the area thoroughly with a clean cloth to remove any dirt, dust, or moisture.

Cut the Patch: If necessary, cut the vulcanizing patch to size, ensuring it is large enough to cover the puncture completely with some overlap.

Apply Rubber Cement: Apply a thin layer of vulcanizing fluid over both the prepared area and the back side of the patch. Allow the cement to sit for a few minutes until it becomes tacky but not fully dry.

Attach the Patch: Press the patch firmly onto the glued area of the tire, ensuring there are no air bubbles trapped underneath. Apply pressure evenly across the patch to ensure good contact.

Cure Time: Allow the patch to cure as per manufacturer instructions, typically for at least 15-30 minutes, depending on conditions and materials used.

Reinflate and Test: After curing, reinflate the tire to its recommended pressure and check for leaks by applying soapy water around the edges of the patch; bubbles will form if there are any leaks.

Final Checks: Ensure that all edges of the patch are securely bonded before using the tire again.