Tire vulcanization repair uses heat and chemicals to bond a patch to a damaged tire. This method creates a strong seal by changing the shape of the rubber solutions. The molecular structure of the rubber changes from a linear to a three-dimensional network structure. Sulfur reacts with the rubber chains, forming strong cross-links. The right temperature, vulcanizing agent, and additives help ensure a good repair. High-quality patches are crucial for a safe and lasting repair. SUNSOUL provides reliable tire patches suitable for a variety of vehicles. This makes tire vulcanization repair both safe and simple.

Key Takeaways

- Tire vulcanization repair uses heat and chemicals to create a strong seal on a damaged tire. This helps keep the tire safe and extends its lifespan.

- Carefully follow each step of the vulcanization process. This helps ensure a lasting and effective repair and prevents future tire problems.

- Choose the appropriate patch and vulcanizing fluid based on the tire damage. This will result in a better repair.

- Vulcanizing a tire is economical and quick. It helps reduce waste and is environmentally friendly.

- If your tire is severely damaged, seek professional help. This ensures your safety and that the repair is done correctly.

How vulcanizing tire repair works

Vulcanization process steps

Tire vulcanization helps repair damaged tires, restoring them to safe use. The process involves several steps to ensure the patch is securely bonded. Here are the steps experts follow for tire vulcanization:

- Clean the area around the damaged area. Remove dirt and debris from the tire.

- Apply a thin layer of vulcanizing fluid to the repair area. Wait for the vulcanizing fluid to become tacky.

- Place the patch in the center of the damaged area. Press firmly to begin the seal.

- Use a tire stitcher to press the patch from the center outwards. This removes air and helps the patch adhere better.

- Remove the plastic protective film from the patch. Sprinkle tire talc on the repair area to prevent it from sticking to other objects.

- Inflate the tire with a small amount of air. Check for leaks to ensure the patch is effective before reinstalling the tire.

Every step in the tire vulcanization process is important. If you skip any steps, the repair may not be lasting and may not be safe. If performed correctly, tire vulcanization can create a strong seal, restoring the tire to normal use.

Tip: Always follow the steps for tire vulcanization. This helps extend the repair’s effectiveness and ensures tire safety.

Vulcanizing tire repair Materials and tools used

Tire vulcanization requires special materials and tools. These items help make the repair strong and durable. The following are the main items used in tire vulcanization:

- Tire repair hand tools

- Inner tube repair vulcanizing patches

- Cold vulcanizing fluid

- Special inner tube repair valves and fittings

- Inner tube repair kits

- Radial tire repair units

- Bias-ply tire repair units

- Plug repair units

- Universal repair units

- Vulcanizing compound

- Buffing cement

- Rubber cord

- Retreading rubber products and specialized chemicals

- Emergency repair kits

- Insertion tools

- Adhesive

- Pre-buffing cleaner

- Bead sealant and liner sealant

- Universal mounting paste

- Liquid mounting lubricant

- Mounting compound

- Tire mounting lubricant holder, brushes, and cotton swabs

- Tire spreader

- Extruder

- Grooving machine

- Vulcstar vulcanizing machine and accessories

All these tools and materials work together to ensure effective tire vulcanization. High-quality patches and vulcanizing fluid (such as those from SUNSOUL) help extend the repair’s effectiveness. Using the correct tools also makes the job easier and safer.

Role of vulcanizing fluid and patches

Vulcanizing fluid is crucial in the tire vulcanization process. This special chemical helps the patch adhere firmly to the tire. The sulfur in the vulcanizing fluid reacts with the rubber, forming a strong bond that holds the patch in place. The repaired tire can then withstand everyday driving.

Patches are also essential in tire vulcanization. Different patches are suitable for different tire problems. Some patches are round, suitable for small holes. Other patches are oval or D-shaped, better suited for larger or irregularly shaped damage. Combination patches and plug units can repair both the inside and outside of the tire simultaneously. Pre-vulcanized patches are easy to use, while raw rubber patches, when heated, can form a stronger seal.

| Patch Type | Pros | Cons |

|---|---|---|

| Standard Round Patches | Easy to use, good for small holes (≤6mm) | Not good for odd-shaped holes; needs careful placement |

| Oval or D-Shaped Patches | Spreads stress better, good for bigger damage | Needs more prep; not found in basic kits |

| Combination Patch-and-Plug Units | Seals inside and fills outside hole | Harder to install; both parts must be set right |

| Pre-Cured vs. Raw Rubber Patches | Pre-cured: easy to handle; Raw rubber: stronger bond | Pre-cured: less mess; Raw rubber: needs heat |

Choosing the right patch and vulcanizing fluid can lead to better tire vulcanization results. SUNSOUL offers a variety of patches, such as chemically cured and dual-cured types. Their split backing design makes them easy to use and helps achieve a tight seal. High-quality patches and vulcanizing fluid protect the tire and ensure driving safety.

Note: Always use trusted brands like SUNSOUL for tire vulcanization. Quality products ensure a stronger and safer repair every time.

Types of tire Vulcanizing tire repair

Hot vulcanizing

Hot vulcanization is the strongest method for repairing tires. Workers use heat and pressure to bond the patch to the tire, creating a tight seal. This process requires temperatures of 140 to 160°C and a uniform pressure of 10 to 15 bar. This method eliminates gaps and prevents rust. Hot vulcanized tire repairs can last up to eight years and withstand pressures up to 3,000 PSI. The tire must be removed from the rim before repair, and the repair area must be cleaned before applying the patch. This method is best suited for large areas of damage or situations where safety is paramount.

| Feature | Cold Vulcanizing | Hot Vulcanizing |

|---|---|---|

| Process | Rubber strips are directly bonded to the pulley | Rubber is heated to bond with the pulley casing |

| Application Cost | Simple process, lower cost | Complex process, higher cost |

| On-site Capability | Emergency repairs can be performed on-site | Emergency repairs can be performed on-site |

| Bond Strength | Weaker, with a risk of detachment | Stronger, achieving 100% rubber tear bonding |

| Service Life | Shorter service life due to poorer bonding effect | Longer service life due to elimination of gaps and improved bonding |

| Risk of Failure | Higher failure risk due to potential gaps and detachment | Lower, as it eliminates seams and reduces corrosion |

Cold vulcanizing

Cold vulcanization is a quick method for repairing tires. Workers use chemically curing patches and a special liquid, without the need for heating. This method is suitable for small punctures and quick repairs. Cold vulcanization can be done anywhere, saving time and money. However, the patch strength is not as strong as hot vulcanization and only lasts six to twelve months. If the tire is used frequently, the patch may fail. SUNSOUL’s chemically curing patches make cold vulcanization simple. The split backing helps with easy patch application.

Vulcanizing tire repair Patches and plugs

Tire patches and plugs repair tires in different ways. Patches are applied to the inside of the tire after it is removed from the rim. Workers clean the repair area, apply vulcanizing fluid, and then press a strong patch into the inside of the tire. Plugs are inserted from the outside using a tool and can quickly seal small punctures. SUNSOUL’s dual-curing patches combine both functions. The split-back design makes it easy to use and provides a good seal.

| Feature | Description |

|---|---|

| Product Reliability | Ensures your safety and extends tire lifespan. |

| After-sales Support | Provides value and assistance to customers. |

| Warranty | Each product comes with a strong warranty and quick response to issues. |

| User-friendly Kits | Easy to use, saving time and effort. |

| Customer Reviews | Positive feedback from users who appreciate fast solutions. |

Choosing high-quality repair products like SUNSOUL tire repair patches ensures longer-lasting repairs and guarantees driving safety.

Pros and cons of vulcanizing tire repair

Vulcanizing tire repair Advantages

Vulcanized tire repair is an economical way to fix tires. Many people choose this method because it saves money. It costs less than buying new tires. The repair process only takes about 10 to 15 minutes. Drivers can get back on the road quickly. The bond formed by vulcanized repair is stronger and more durable than quick fixes. This helps the tires wear evenly. Even wear makes the car ride smoother and safer. Repairing tires instead of discarding them helps protect the environment. It reduces waste and keeps the environment clean.

| Advantage | Description |

|---|---|

| Affordability | The cost of repairing a tire is significantly lower than buying a new one. |

| Speed | Vulcanized tire repair typically takes 10 to 15 minutes, depending on the extent of the damage. |

| Maintains even wear | Ensures all tires wear at the same rate, improving car performance. |

| Durability | Provides a strong and long-lasting repair compared to quick fixes. |

| Environmental Impact | Extends tire lifespan, reducing waste and protecting the environment. |

Vulcanized repair is also effective in harsh environments, such as off-road conditions. The strong seal prevents blowouts and ensures driving safety. The initial cost may seem high, but the repair is long-lasting. This means you buy fewer tires and spend less time repairing them. Repairing tires also reduces waste, thus protecting the environment.

| Repair Method | Durability | Failure Rate |

|---|---|---|

| Vulcanizing Patch | Lasts a long time | Low |

| Tire Plug | Lasts a few months | High |

| Liquid Sealants | Temporary | High (can fail easily) |

For those who want to extend the lifespan of their tires and protect the environment, choosing vulcanized tire repair is a wise choice.

Vulcanizing tire repair Disadvantages

Vulcanized tire repair also has some drawbacks. If the tire is severely damaged, its safety may not be as good as a new tire. Old damage may cause the tire to wear out faster. Some companies may not offer warranty service after vulcanized tire repair. This means drivers may not get help if they encounter problems in the future.

- Increased safety risks if the tire is severely damaged.

- The repaired tire may wear out faster.

- Vulcanized repair may void the tire warranty.

Drivers should weigh the pros and cons before choosing vulcanized tire repair. For severe damage, consult a professional to ensure safety.

Tire damage and repair suitability

What vulcanizing can fix

Vulcanization repair technology is very effective for certain tire problems. Technicians use this technique to repair tread punctures and liner wear. When done correctly, a vulcanized tire is almost as strong as a new tire. Most tread punctures can be repaired this way. Drivers like vulcanization repair because it is reliable and durable.

Common tire damages that can be repaired by vulcanization include:

- Localized repair: Used to repair deep cuts in the tire cords. The success rate is approximately 95%.

- Spot repair: Used to repair external damage that does not affect the cords. This includes sidewall cuts and bead damage. The success rate is over 99%.

- Delamination repair: Used to repair cases where liner wear exposes the cords. Almost always successful.

Experienced technicians can repair most tread punctures and minor liner wear. Vulcanization repair works best if the damage is in the tread area and not too large.

| Damage Type | Repair Suitability | Success Rate |

|---|---|---|

| Tread punctures | Very good | Over 95% |

| Cord cuts | Good | 95% |

| Bead damage | Good | 99% |

| Inner lining wear | Good | Over 99% |

Vulcanization repair helps ensure driver safety and extends tire lifespan.

When vulcanizing is not recommended

Vulcanization repair is not a cure-all and cannot fix all tire problems. Safety is paramount, so certain damages should not be repaired this way. Only punctures in the tire crown area can be repaired. Punctures in small tires must not exceed 1/4 inch in diameter. Punctures in large truck tires must not exceed 3/8 inch in diameter. Sidewall damage cannot be repaired because the sidewall flexes and lacks sufficient strength.

Only repairs in the tread area are safe. The hole must be at least half an inch from the edge. Damage to the sidewall or shoulder cannot be repaired. Attempting to repair unsuitable damage is dangerous. Poor repairs can lead to blowouts, especially at high speeds. This can cause the driver to lose control. The National Transportation Safety Board (NTSB) has documented accidents caused by improper tire repairs.

Problems such as bubbles and uneven heating can weaken the tire. If the chemical bonds fail, the tread may detach under stress. Good quality control helps prevent these problems.

- Punctures outside the tread area cannot be repaired.

- Sidewall and shoulder damage should not be repaired.

- Oversized holes cannot be repaired.

- Bubbles and poor adhesion can make the tire unsafe.

Can all tire damage be repaired by vulcanization? No. Only some tire damage can be safely repaired through vulcanization. Drivers should always consult a professional before attempting tire repair.

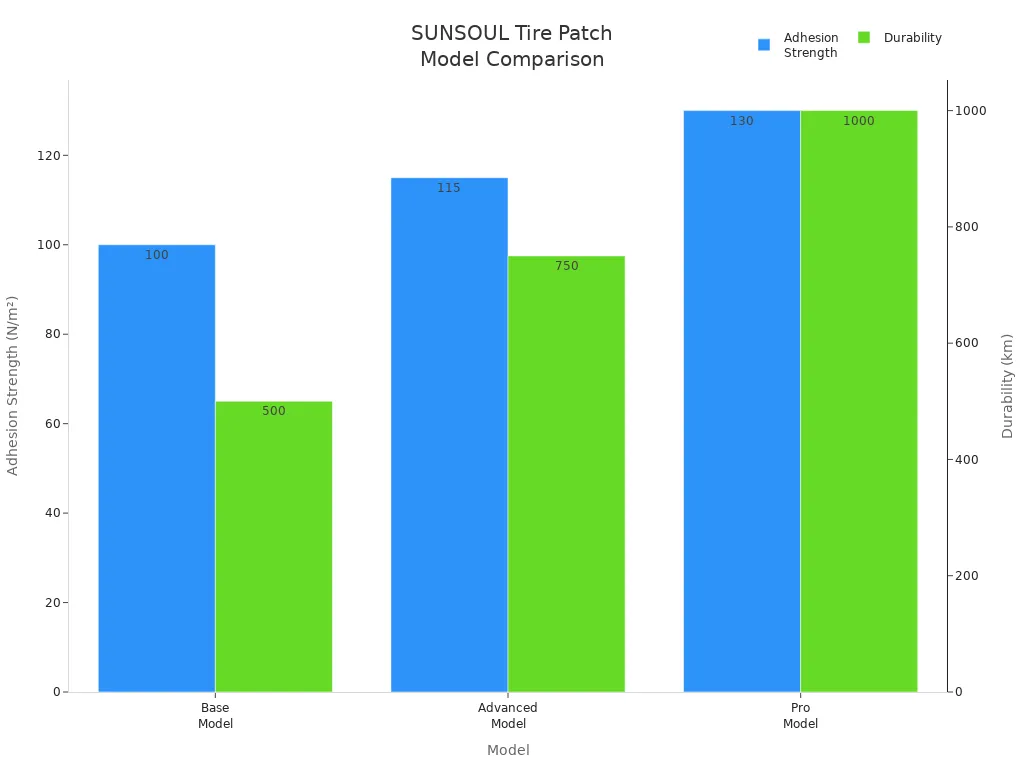

Vulcanization repair is effective for small punctures. SUNSOUL tire repair products help improve tire safety and extend lifespan. They provide strong adhesion, feature robust fabric materials internally, and come with a 24-month warranty.

| Feature | Description |

|---|---|

| Excellent Adhesion | Strong bond stops leaks and keeps you safe. |

| Vulcanization Process | The repair can handle high heat and pressure. |

| Textile Reinforcement | The patch is tough and does not wear out fast. |

| 24-Month Warranty | The patch works well for a long time. |

Drivers need to choose the appropriate repair method based on the type of tire damage. A trained technician should inspect the tire and use the correct tools. For serious damage, seeking professional help is the safest approach.

FAQ

How long does vulcanized tire repair last?

Vulcanized tire repairs can last for many years. SUNSOUL tire repair patches provide a strong and durable bond. Drivers can ensure safe and long-lasting tires by using these patches.

Can anyone use SUNSOUL tire repair products?

Yes. SUNSOUL patches are easy and convenient to use. The split backing design allows users to quickly apply the patches. Clear instructions help beginners easily repair tires.

What types of damage can SUNSOUL tire repair patches fix?

SUNSOUL tire repair patches can repair tread punctures and small cuts. They can also repair worn inner liners. Technicians say these patches are suitable for most tire problems. They work for cars, trucks, bicycles, and other vehicles.

Is vulcanization safer than using tire plugs or sealants?

Vulcanization creates a stronger seal than using tire plugs or sealants. SUNSOUL tire repair patches help prevent leaks and blowouts. Drivers choose vulcanized tire repair for safer and more durable tires.

Why should drivers choose SUNSOUL tire repair patches?

SUNSOUL tire repair patches provide a strong bond and are easy to use. They come with a 24-month warranty. Drivers can drive with peace of mind while saving money. SUNSOUL provides fast assistance and excellent service.